by NewsAdmin | Jul 26, 2023 | Jendamark Junction

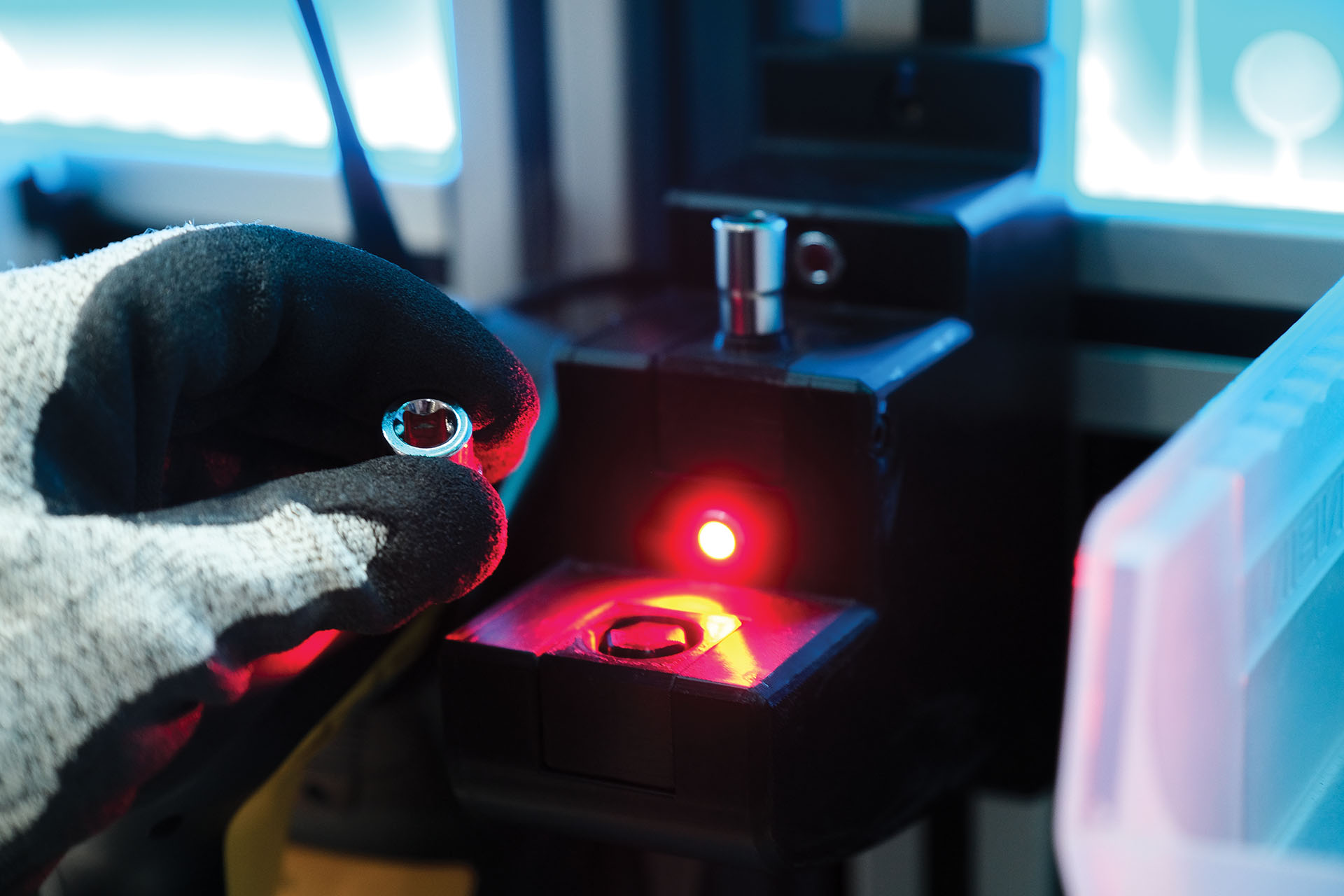

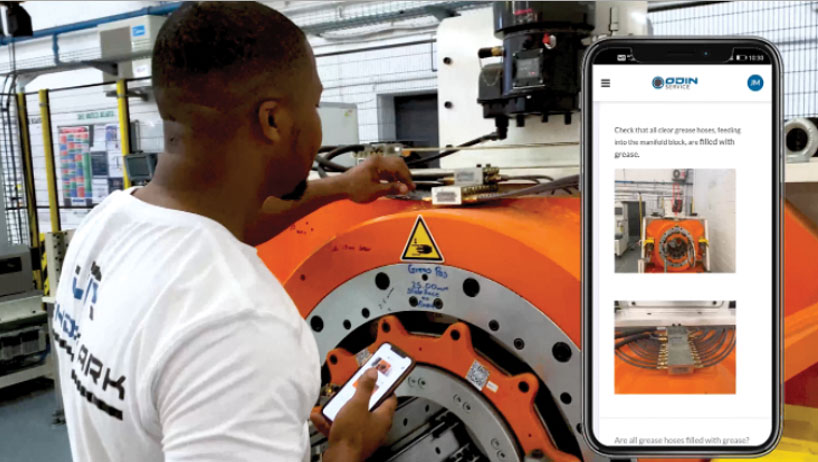

The introduction of ODIN Workstation on a new differential assembly line for our customer, ZF, at their plant in Gainesville, USA, has made a big difference to the operators on the shop floor.

According to ZF’s senior production support specialist, David Pirkle, the human-centric approach is not only helping operators to do their jobs better but is also helping the plant to achieve its overall key performance indicators.

“We concentrate on four Lean manufacturing principles: We want a safe plant that doesn’t put the customer at risk, that makes good quality products, and we want to be able to do this at a good cost, and in time. If we achieve those four KPIs at a high level, then we’ll have customer satisfaction.”

Pirkle says taking a human-centric approach by first supporting operators is essential to achieving this success.

“If we continue to make their job easier, we’ll get the KPIs we want.”

Paperless work instructions

Paperless work instructions

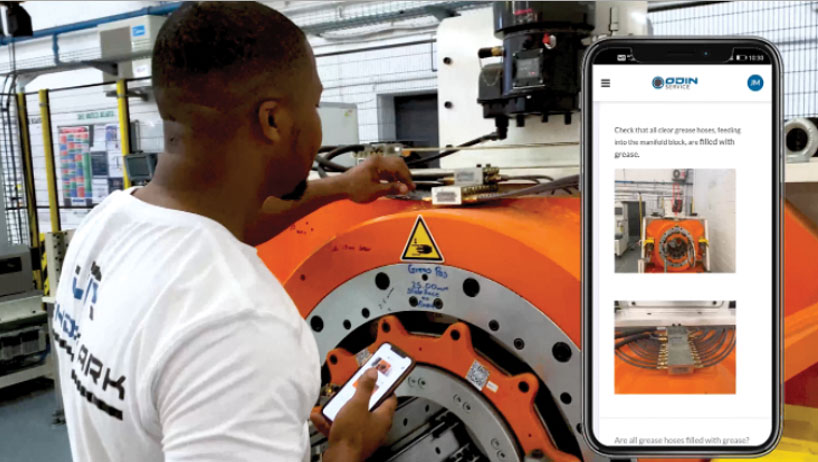

While some were initially resistant to the switch from paper-based work instructions to a step-by-step digital process, Pirkle says even the longest serving operators have seen the difference it has made, since they no longer have to memorise the steps.

“One operator, he’s a little old-school, came back and said this was actually easier than paper. So I was happy to hear that because I really value him – he’s been with ZF for 35 years.”

Pirkle said ODIN Workstation provided practical support for operators, helping them follow a set sequence to build quality products in a safe way, within cycle times.

“ODIN is right in front of them, showing them what to do. The operators can basically build and look at the same time.

“It also allows you to train less, because the work instructions are in front of you, they’re easy to read and simple to understand. If something doesn’t go right, ODIN tells you what you’ve missed. It won’t allow you to move to the next step unless you do the previous one.”

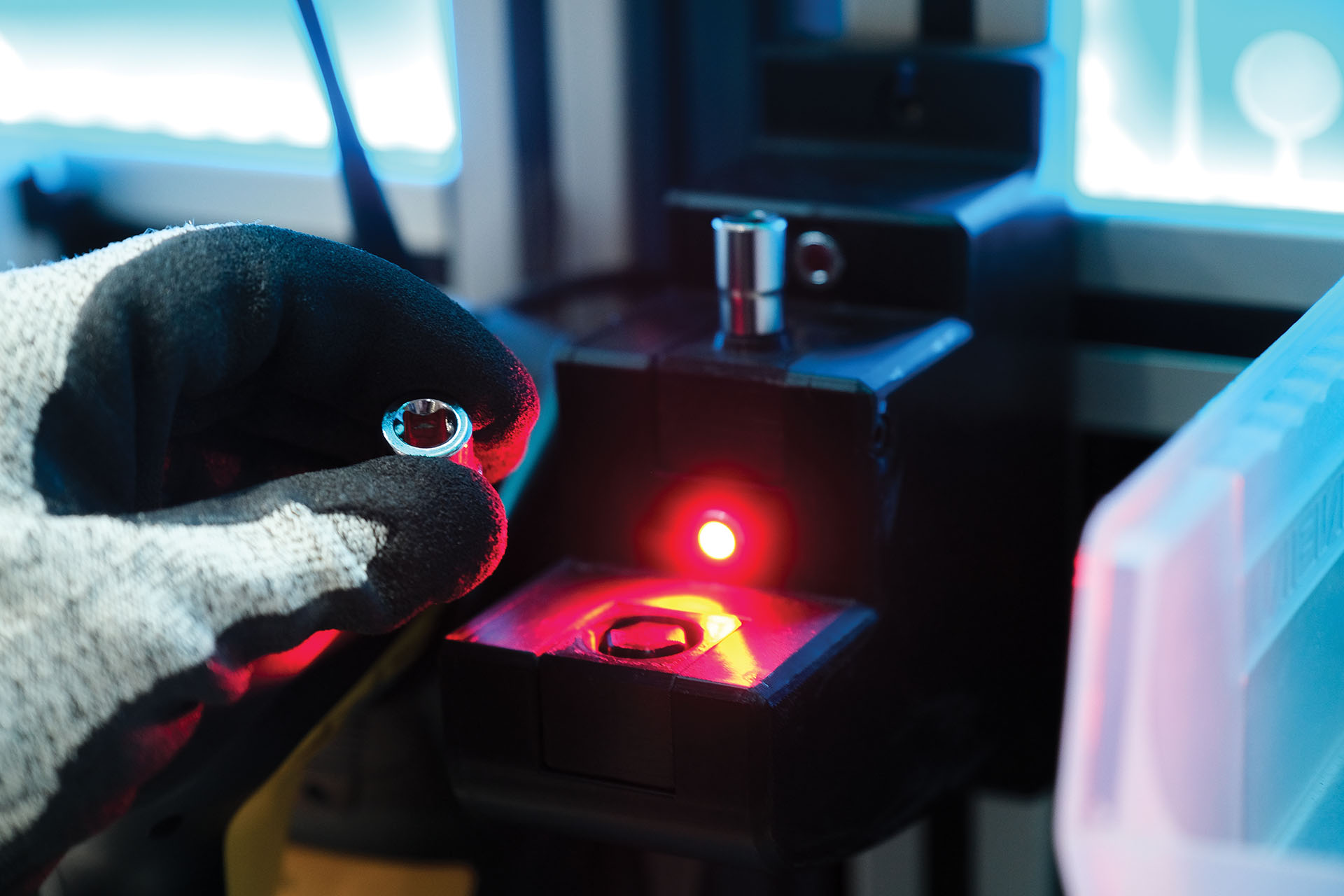

Aside from work instructions, ODIN Workstation secures the process via validation of parts and sub components. Traceability of every step allows visibility into process, product and machine trends generated from automated, semi-automated and manual operations.

TPM and 5S checks

TPM and 5S checks

ZF also worked with Jendamark to develop a new system within ODIN for ensuring that operators complete their required Total Productive Management (TPM) and 5S System checks, to ensure that their space is clean and organised so work can be performed efficiently, effectively and safely.

“The operator comes in in the morning, and they’ll do their quick 5S checks. Then they click ‘Yes’ to accept responsibility for the state of their work area and start their shift. This drives accountability, and we’ve seen a really good response,” explains Pirkle.

“The supervisor loves it because he doesn’t have to walk around the line and he doesn’t have to check the boards; the information comes to him. Because a lot of the data is in ODIN, which can produce graphs and charts for reporting, supervisors can actually supervise again and not be so tied down with admin.”

Given the benefits that the Gainesville plant has seen, ODIN Workstation will also be adopted at its sister facility in Marysville.

GLOBAL TEAMWORK

This assembly line was an example of Jendamark’s global teamwork – designed, built and installed by our South African team, with the high quantity workpiece carrier units manufactured in India.

It was also installed in record time – 7.5 weeks from the time the first box arrived until the last button was pushed and final sign-off achieved.

Project manager David Boshoff says the recipe for success was testing and more testing. “Through proper strain testing at our home premises, we could de-bug the line and avoid a costly, extended installation.

“This was our first time using VMT to scan and evaluate the sealant bead. Getting the spintop working on site brought many unknowns and was challenging, but the team dug in and resolved all issues.”

Boshoff says pandemic-related visa restrictions meant that all installation team members had to climb in to make it happen. “We had controls guys wiring panels, mechanical building parts and electrical helping with line layouts.”

A further headache was the delayed arrival of a third-party supplier’s robots.

“It was a challenge placing the conveyor in the exact location, within 10mm, to ensure that they could reach pick-up and drop-off. We had to measure and re-measure many times before placing the conveyor and then all the facilities. Moving the entire line again was out the question.”

by NewsAdmin | Jul 25, 2023 | Jendamark Junction

Jendamark’s manufacturing technologies have been independently recognised for a second consecutive year by the prestigious Africa Tech Week Awards in Cape Town.

At the ceremony in May, Jendamark won the Technology Innovation of the Year category for our ODIN Manufacturing software, making it two in a row after being named Technology Company of the Year for 2022.

Innovations director Yanesh Naidoo says the award, judged by an independent panel, serves as a confirmation that the manufacturing technology developed by Jendamark is meeting a real need for small to medium enterprises.

“For us, it’s not about developing technology for technology’s sake, but about understanding the customer’s challenges, and creating digital solutions to solve those challenges.

“Last year, the award was about our company; this time it’s for our products. So, it’s a massive win for us,” says Naidoo.

For developing countries such as South Africa and India to prosper, he says, there is a need to focus on building a strong manufacturing-based economy.

“That’s why we developed ODIN Manufacturing – to help digitise and improve production efficiencies, and create opportunities for the massive human capital that we have.

“Our solutions take a human-centric approach to Industry 4.0, meaning they don’t take people off production lines but rather use tech to support people to do their jobs more accurately and efficiently.”

Jendamark’s ODIN Education division, which creates the tech infrastructure to bridge the digital divide in underprivileged schools, was also named a finalist in the ed-tech category.

“Although they may seem unconnected, we created ODIN Education to help transform the education sector, so that the next generation can be equipped and ready to take on this manufacturing challenge amid the rapidly accelerating pace of Industry 4.0 technologies,” says Naidoo.

by NewsAdmin | Jul 24, 2023 | Jendamark Junction

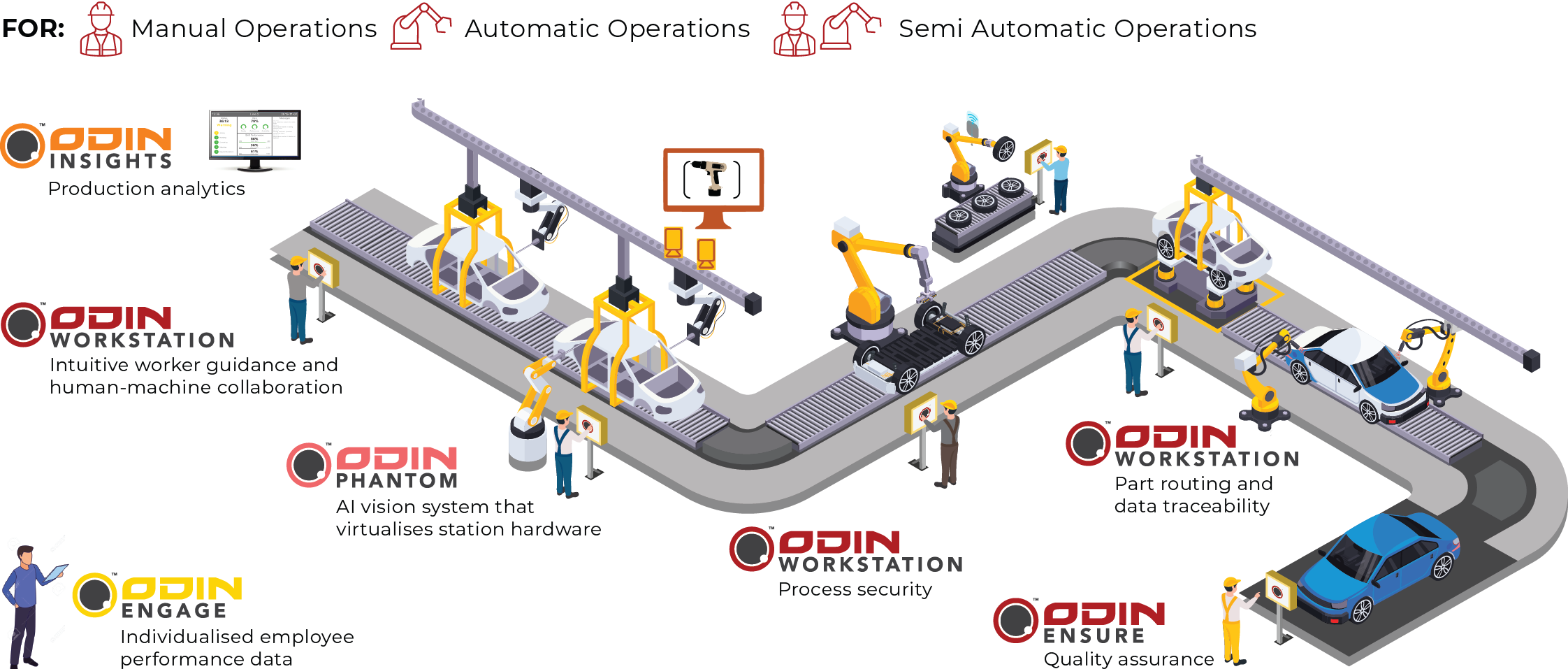

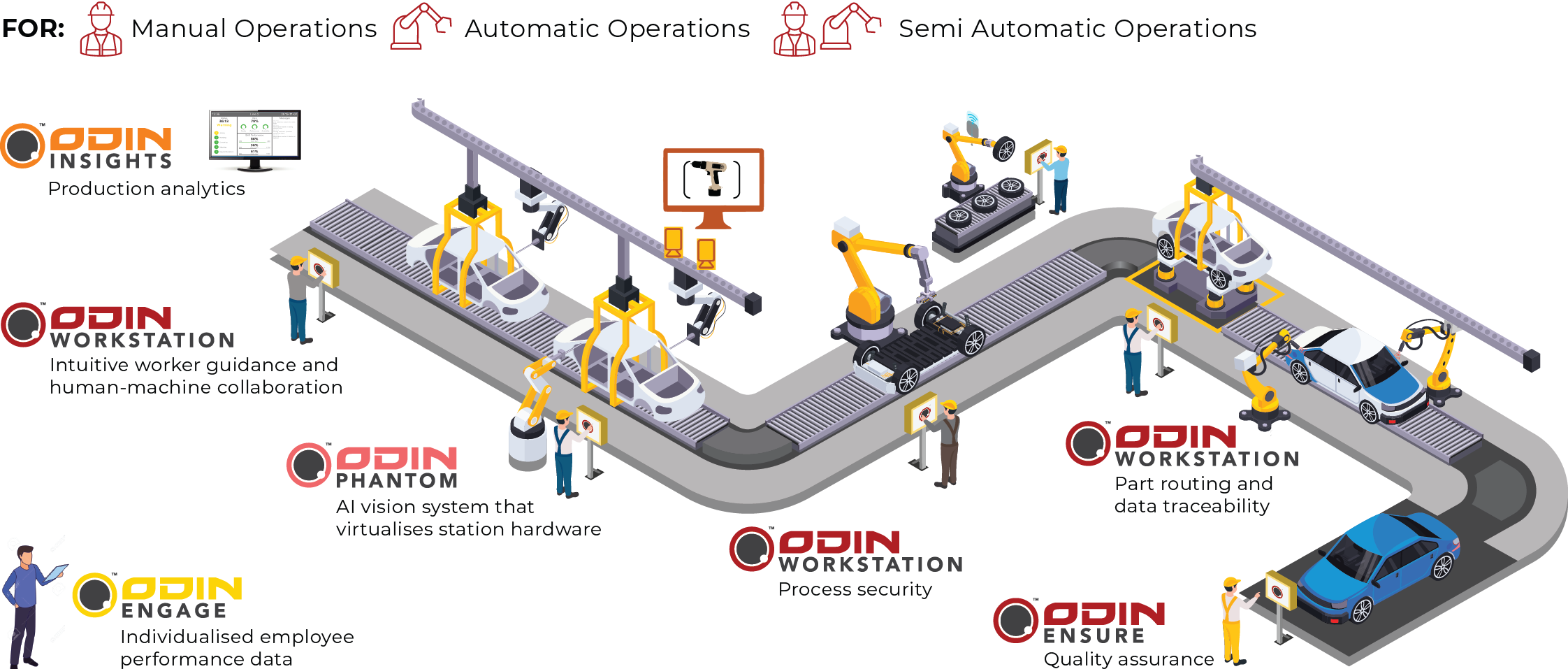

Jendamark’s ODIN Manufacturing is designed to provide digital solutions to real-world problems on our customers’ factory floors. To make the ecosystem more accessible and easier to implement for customers, the offering has been restructured into two distinct clusters of support.

Head of ODIN Manufacturing Juane Schutte says the solutions can be broken down into those that support complex, discrete manufacturing processes and those that support critical maintenance and shopfloor tasks.

“We’ve identified these two distinct problem areas where our customers need support,” explains Schutte.

“If you need support for your production process, we recommend the base product, ODIN Workstation, and if you are looking to digitise your maintenance function, then we start you off with ODIN Checkpoint.”

Depending on the customer’s unique situation, Schutte says, a combination of various add-on products can be incorporated to provide a tailored solution. Below is an overview of how ODIN Manufacturing can solve common production or maintenance challenges.

PRODUCTION SUPPORT

When it comes to production processes, the base product is ODIN Workstation – a digital infrastructure solution that increases efficiencies on your production line. Its core features are enhanced operator guidance, quality assurance, direct device integration and production planning.

As a standalone product, ODIN Workstation provides a multitude of capabilities and features, while its add-on solutions unlock further potential.

For example, if you are struggling with defective parts due to incorrect orientation during assembly, the ODIN Phantom AI vision system could assist with process tracking, while ODIN Ensure digitises your end-of-line checklist to improve traceability and process security for your quality assurance process.

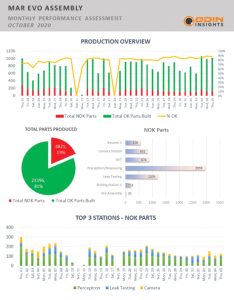

ODIN Engage tracks the performance of individual operators, so that you can support them by identifying areas for improvement and training, while ODIN Insights provides comprehensive production-level reporting to accelerate root cause analysis when there are problems and to minimise downtime.

MAINTENANCE SUPPORT

As the stand-alone base product to improve the support processes around your factory, ODIN Checkpoint is a user-friendly, cloud-based solution for preventative and predictive maintenance. Set, track and control all your maintenance and service tasks to prolong the lifespan of your assets.

You can assign and schedule planned maintenance activities without reams of paperwork. If your senior technicians are not available, digitised work instructions can help junior members carry out more complex service tasks.

When it comes to urgent, unplanned breakdowns, the Raise Alert system can be used to notify relevant team members of the problem and assign someone to take action. ODIN Checkpoint helps your technicians become accountable for performing planned maintenance tasks effectively and in time and for managing unplanned incidents. Detailed reporting and analytics gives managers a clear picture of both the technicians’ performance and the health of all assets in your factory.

The addition of the ODIN Raven sensor, which works with our ODIN IOT software, turns machine vibration data into useful information that allows your team to detect anomalies and take pre-emptive action.

by NewsAdmin | Jul 21, 2023 | Jendamark Junction

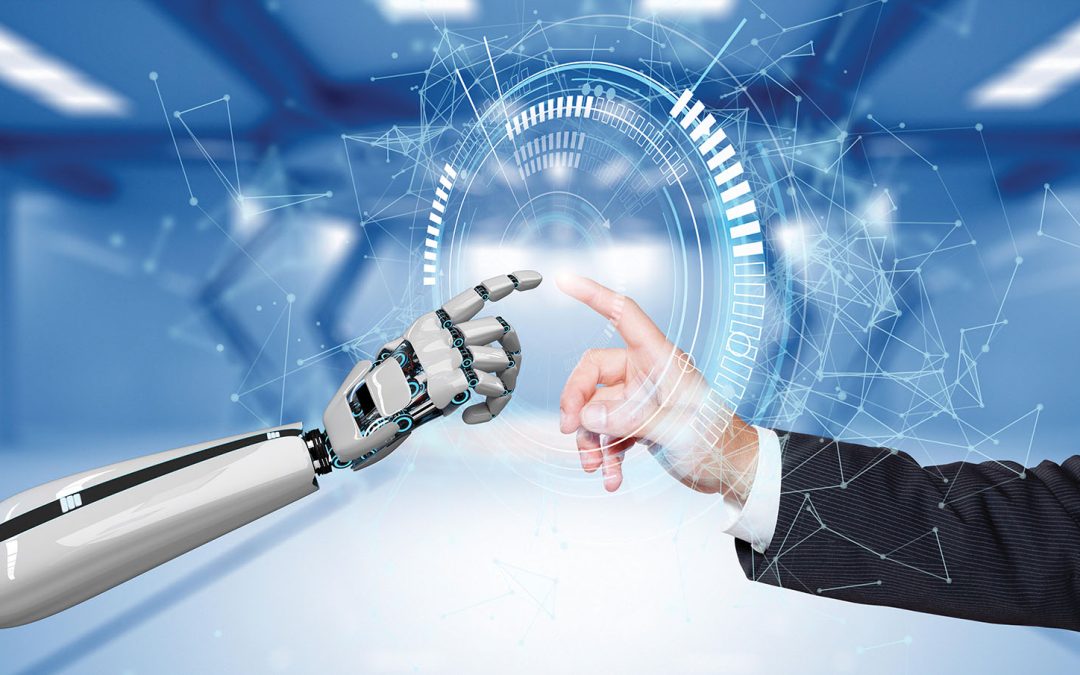

While many equate Industry 4.0 with robotics and full automation, Jendamark’s human-centric approach puts people at the beating heart of the manufacturing process. Humans will always have an important contribution to make – despite the rise of artificial intelligence (AI).

When it comes to a realistic assessment of the role that humans play, one must first acknowledge that humans have been, and will continue to be, an integral part of manufacturing, argues Jendamark India director Himanshu Jadhav.

“Throughout history, humans have solved problems and created technologies to make life easier – to meet a need. Even with the smartest manufacturing facilities, it is the humans in that environment that make it a success,” says Jadhav.

“This is especially true when it comes to complex, qualitative scenarios,

which require all facets of human intelligence to resolve.”

Emotional advantage

Emotional advantage

On the one hand, machines, unlike people, do not get emotional, and their output is not dependent on how they were feeling at the start of the working day, he says.

“Like their human co-workers, machines with AI can now identify production problems and stop the process until the problem is rectified,” concedes Jadhav.

But, he says, arriving at the solution to that problem involves choosing the best method with the least impact, identifying the priority actions, and possibly weighing up several variables. These are complex scenarios that require creativity, emotion and sound judgement. Many situations can’t be solved by an algorithim.

“We rarely see EMOTION as an admirable human quality. But, in manufacturing, it is often the difference between doing something wrong and creating a viable alternative solution.”

Emotion, it seems, is the human motivator for problem solving. We engage in out-of-the-box critical thinking and do “impossible” things because of emotional drivers, such as passion and curiosity.

Economic contributors

With the populations of developed economies declining, and the number of skilled workers in the manufacturing sector declining with them, autonomous production processes fill a real need by doing more with fewer human resources, explains Jadhav.

“Having said that, it takes a highly skilled human to develop, operate and maintain an automated machine. While humans are less involved, they still have a critical role to play as the process demands a more advanced skill set.”

Technology is getting smarter every day, so keeping up with and implementing it is the main role of humans in so-called first world countries.

In developing economies, which tend to have much larger, less skilled populations, Jadhav says less automation along with more employment and job creation are critical to improving socio-economic conditions and general living standards.

“Here, humans must be more involved in manufacturing, being in control of mostly manual production processes, to facilitate overall economic advancement.”

As production systems evolve, he says, people and technology are being integrated more closely and intensively than ever before.

“It’s essential that we fully understand how to best design and operationalise both human and technological functions.”

Why Jendamark’s human-centric approach works

Let’s review the numbers

3: The decades of machine-building experience that Jendamark has

3000+: The number of assembly facilities built

95%: The average efficiency rate of our machines over a period of time

75%: The average efficiency rate of human operators over that same period

Production output = human efficiency rate x machine efficiency rate

Improving overall efficiency

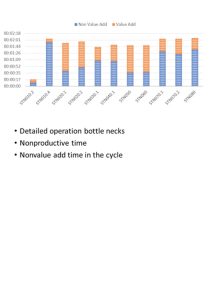

For machine builders such as Jendamark, it is relatively easy to improve machine efficiency using smart technology. But this will not significantly improve production output if the human efficiency remains low.

That’s why ODIN Manufacturing solutions focus on supporting humans through worker guidance and process security solutions to eliminate errors and improve the overall quality and quantity of the end product.

We understand that literacy levels, skill sets and expertise vary, so our software solutions make it extremely easy for even novice operators to complete assembly tasks with fewer errors and highest efficiency.

Process security

By connecting field devices like cameras, sensors and machines, we create an ecosystem that ensures that none of the assembly process steps can be skipped. These process security checks also apply where collaborative robots are employed in conjunction with ODIN Manufacturing. Where the robot is assigned to a particular station, the camera will check the process security measures, which are recorded in the ODIN system.

Must-have solutions

By implementing these two core solutions, customers can improve not only production efficiencies but also the efficiency of the plant.

ODIN Workstation:

ODIN Workstation:

Ensures that even a new operator is able to do an assembly task with minimal or no training. Unless every process step is correct, the part does not leave the station.

ODIN Checkpoint:

Ensures that the machines are well looked after. This is a cloud-based maintenance solution for scheduling tasks and guiding inexperienced technicians to perform complex maintenance tasks.

by NewsAdmin | Jul 19, 2023 | Jendamark Junction

While there has been a lot of hype around Industry 4.0, the digitalisation of factories has not scaled up as expected. A fundamental misconception of what it’s all about and a slow-to-change mindset are two of the major impediments to successful implementation.

A flood of new products on the market and a misplaced focus on the technologies themselves – rather than their practical uses – leaves many customers overwhelmed, says Jendamark innovations director Yanesh Naidoo.

“There are a lot of buzzwords, like the integration of IT and OT on the shop floor, and I think people get befuddled by all the jargon and consulting talk,” Naidoo says.

“Simply put, Industry 4.0 is just a set of technologies that you can use to solve your manufacturing problems.”

A tech toolbox

It helps to think of Industry 4.0 as a toolbox with a set of tools inside, he explains.

“However, having a toolbox full of tools mean nothing unless you do something with them. You must first understand the problem you’re trying to solve in your factory, and then invest in the right tool for the job.

“A hammer has many uses, but how you apply it depends on your situation. Also, you may be trying to hammer in a screw, when what you really need is a screwdriver.”

For example, if frequent machine breakdowns are a problem, Naidoo says an anomaly detector could help to highlight a downward trend in performance, which could be addressed and fixed before it becomes a serious problem, avoiding unnecessary downtime.

Proactive vs reactive approach

“Essentially, Industry 4.0 is about using tools to be more proactive, rather than reactive. But it all means nothing if our mindset doesn’t change.”

Naidoo draws parallels with the preventative approach to health and longevity outlined in Dr Peter Attia’s book Outlived.

“Medicine 2.0 has been extremely successful in treating lifestyle diseases such as Type 2 diabetes. You go to the doctor, they diagnose you and give you insulin, which has saved many lives.

“But this book argues for a transition to a more preventative approach to medicine. Don’t wait to get diabetes; monitor your health, get the check-ups, make the necessary dietary and lifestyle changes, and prevent it from happening in the first place.”

Factory health screening

Until now, manufacturers have not had the technology or toolbox to take a preventative approach to maintaining the overall health of their factory assets, but Industry 4.0 is changing all that. The difference, Naidoo says, lies in the data that comes from continuous measurement rather than a static, point-in-time measurement.

“A factory audit, like a glucose test for diabetes, is not an accurate reflection of your lived reality,” he says.

“For the glucose test, you fast the night before, then go for the blood test. If your results are just within the acceptable range, everything is deemed fine, so you revert to your bad dietary habits. You’ve prepared your body for the test but that’s not how you live your life, and you can expect future problems if you don’t continuously monitor your glucose levels and make lifestyle changes,” explains Naidoo.

Similarly, he says, a factory audit usually runs quality and production checks using the best operators, the best maintenance team, and the best raw materials on the line.

“It’s a fake perception. What you need is live information from the production line that can be used to understand where the problems are and improve the process by making iterative changes.”

The problem with OEE

With the right technology in place, everything on a production line can be measured continuously – from operator speed to press force and scrap rates. The problem, Naidoo believes, is that every plant manager’s performance is measured on Overall Equipment Effectiveness (OEE), which is a widely used, retrospective, reactive measurement.

“It tells you what happened yesterday, but nothing about what is going to happen tomorrow. Plant managers should be measured on what is going to happen, because they can still have an impact on that.”

Like the human body, all production lines are not the same, so trying to meet a set OEE key performance indicator of, say 85%, might not be practical, given the age of the line, or the quality of the incoming raw material.

“The measurement needs to be unique to a particular production line. As the line gets older, there’s more wear and tear, and breakdowns. So, you need dynamic baseline data that reflects the current situation and can be improved year on year.”

Naidoo says technology can help to predict the risks associated with the people, machine, and product parameters on the shop floor. “Then you can proactively do things to mitigate the risk before it happens.

“We know everyone is under pressure to produce. But at some point, when you see the data trends going in the wrong direction, a manager must have the foresight to make the decision to stop the line and fix the problem, knowing it’s eventually going to hit the limit.

“It’s critical to be proactive because when it hits the limit and things break, you will stop the line. And you will have to make the time and budget to fix it. You’ll have far less downtime if you make adjustments when you notice a spike in anomalies, even if they’re still within tolerance.”

Competitive advantage

Ultimately, Naidoo says, Industry 4.0 is a must for manufacturers who want to remain in business in a rapidly changing environment.

“The world is getting far more competitive. You have to squeeze every single cent you can out of your production process. One of the key things is to become more agile because variation of product, or mass customisation, is now a demand from customers. Your production line needs to be able to adapt quickly and effectively, and also manage fluctuating volumes, without massive capital cost or too much downtime.”

So, what does practical digitalisation look like and where does one start?

If a customer is still hesitant to make changes on the production side, Naidoo says one easy entry point is digitising the maintenance function to facilitate the scheduling of tasks and a more preventative approach to asset health.

“Then once you start seeing the benefits, you can start optimising your assembly process efficiencies by introducing, for example, operator guidance systems. If you choose the right supplier and technology, digitalisation is designed to start small and grow with you step by step, so you get your return on investment.”

by Good News Lab | Feb 11, 2020 | Industry 4.0, Jendamark Junction

With the Indian government offering attractive incentives to electric vehicle (EV) buyers, Jendamark India is rapidly becoming a trailblazing player in the country’s quest for cleaner energy.

India’s proposed EV incentive scheme is set to offer significant tax breaks for consumers on the road to achieving a targeted 30% share of all new vehicle sales by 2030.

“Our government is really pushing this issue,” says Jendamark India’s CEO, Himanshu Jadhav. “To achieve this, the government is planning to reduce general sales tax on EVs from 12% to 5%. A few months ago, it was reduced to 12% from 18%.”

Another proposal already implemented is that those buying electric vehicles will receive an additional income tax deduction of Rs 1,50,000 on the interest paid on loans taken to buy electric vehicles.

As a result, he says, buyers are warming to the idea of this new vehicle technology.

“According to a recent survey, 50% of car buyers in India are ready to switch to EVs if the infrastructure is available.”

GOING GREEN

But, incentives aside, the global population in general has a growing awareness of the need to go green.

“Awareness and sensitivity towards climate change and pollution issues is a hidden force for the surge in EV market. Every individual globally wants to reduce his or her carbon footprint,” says Jadhav.

This burgeoning market has seen original equipment manufacturers (OEMs) in India venturing into and ramping up their EV production, which has had a knockon effect for suppliers forced to embrace these new technologies.

Jendamark India has been at the leading edge of these industry developments, designing and building the first battery pack and power electronics assembly line in the country for Mahindra Electric Mobility Ltd.

Power electronics consist of a charger, variable frequency drive and all electrical signal processors which power the vehicle, whereas a power pack is a cluster of batteries put together as a pack which powers the vehicle.

“Battery pack assembly is new technology in India and local equipment manufacturers are not available for EV manufacturers in India, so we have had to depend on European and Chinese equipment suppliers,” Jadhav explains.

“However, Jendamark has invested strongly in the research and development, design and manufacturing of such equipment in India. Our Industry 4.0-enabled assembly lines are helpful in increasing production and lowering the manufacturing cost of battery packs that fit in EVs.”

In fact, battery costs are expected to be cut by half while performance is expected to double over the next decade.

BUILDING BATTERIES

Jendamark’s global head office in South Africa has played an integral role in the design process for Jendamark India’s first EV power pack assembly lines, providing the benefits of its three decades of automotive expertise where needed.

“Following the design phase, we recently built and supplied two assembly lines, both manufactured in India, and are in the process of executing an expansion project for the addition of new variants on the existing lines,” says Shashikant Chaudhari, who was Jendamark India’s management representative on this project.

The human component has also not been overlooked when it comes to technological development.

“Batteries being assembled carry charge. Human safety is very important when you handle charged batteries. Using Jendamark’s own digital manufacturing software, Odin, we monitor and instruct operators in following right assembly sequence to ensure their safety.“

While venturing into new territory has had its challenges, Chaudhari says it has been an exciting journey so far.

“Jendamark is an expert in powertrain solutions for internal combustion vehicles, while EVs have a completely different powertrain. But EVs have brought us tremendous new learning opportunities.”

FACT BOX: CLEARING THE FOG

At the heart of India’s push towards EVs is the government’s all-important clean energy policy aimed at reducing toxic pollution levels.

- Severe traffic congestion in India’s major cities can result in average trip speeds of less than 20 kilometres per hour.

- At such speeds, vehicles emit four to eight times more than they would under less congested conditions.

- Vehicles also consume more fuel per trip and produce a higher carbon footprint due to congestion.

- According to the website India Today, on Diwali night 2019, many areas of Delhi recorded an Air Quality Index of 999 – 16 times higher than the prescribed limit.

Paperless work instructions

Paperless work instructions TPM and 5S checks

TPM and 5S checks

Emotional advantage

Emotional advantage

ODIN Workstation:

ODIN Workstation: