Catalytic Converter Assembly Systems

Adaptive canning has become a watchword in the automotive industry as OEMs require increasingly complex catalytic converters to comply with the emission control regulations in different markets. Jendamark has developed a range of flexible, automated assembly solutions to help customers keep pace with the changing demands.

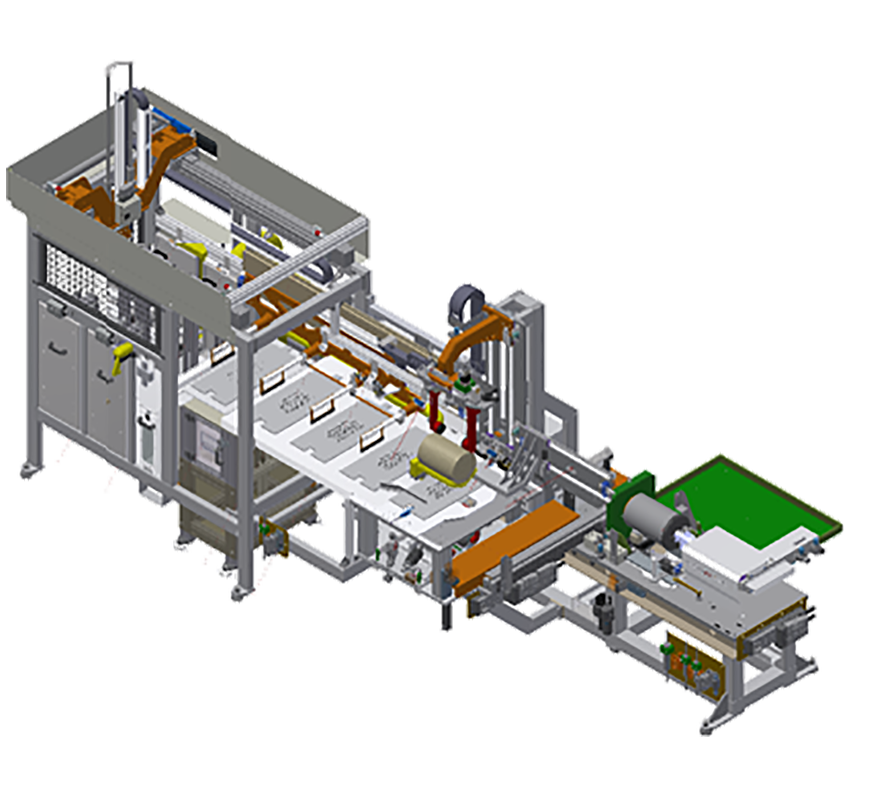

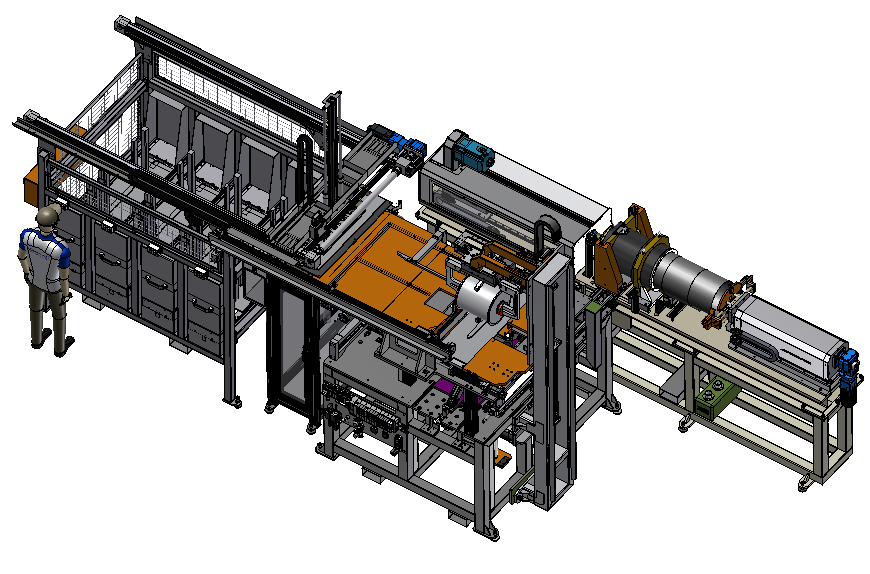

Canning Lines

Standard Canning Modules

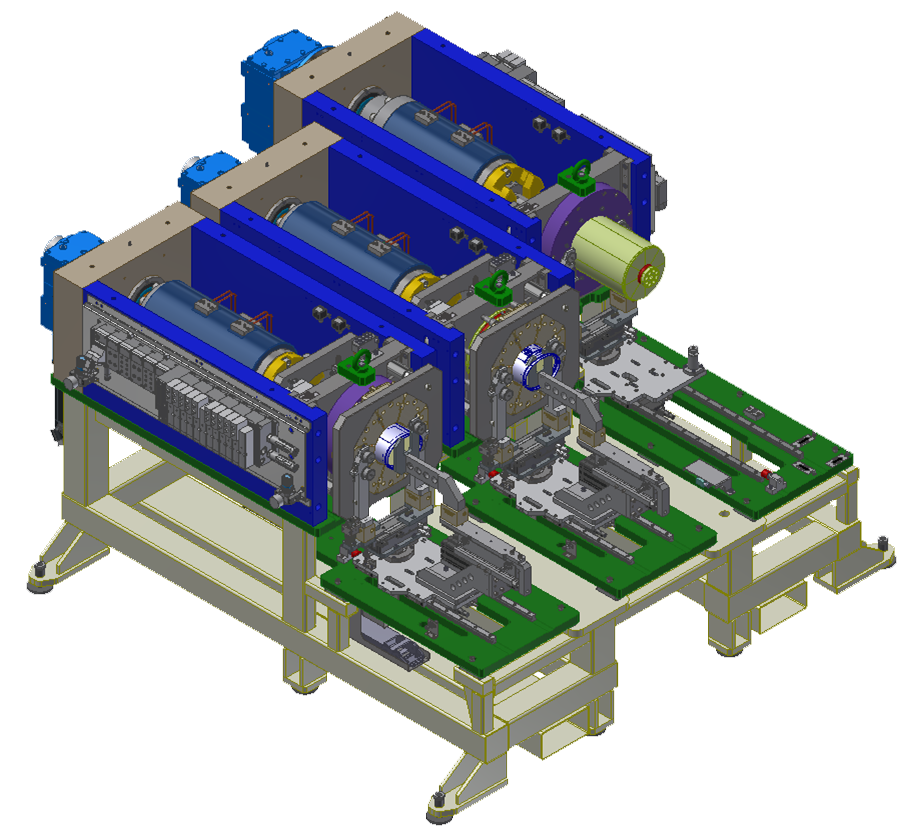

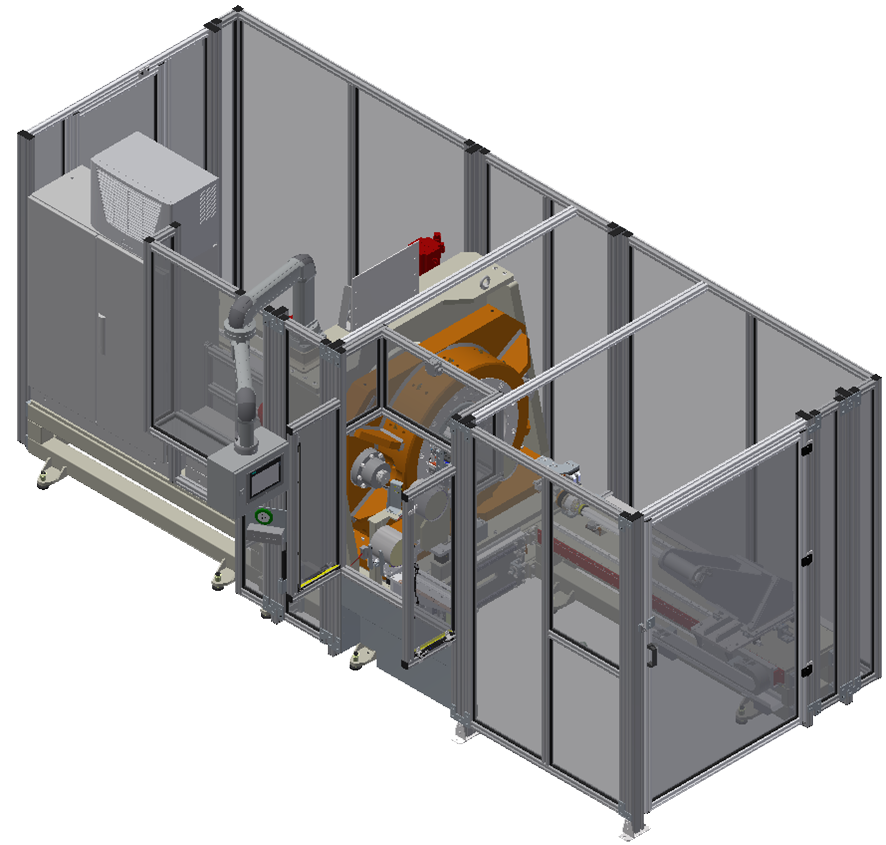

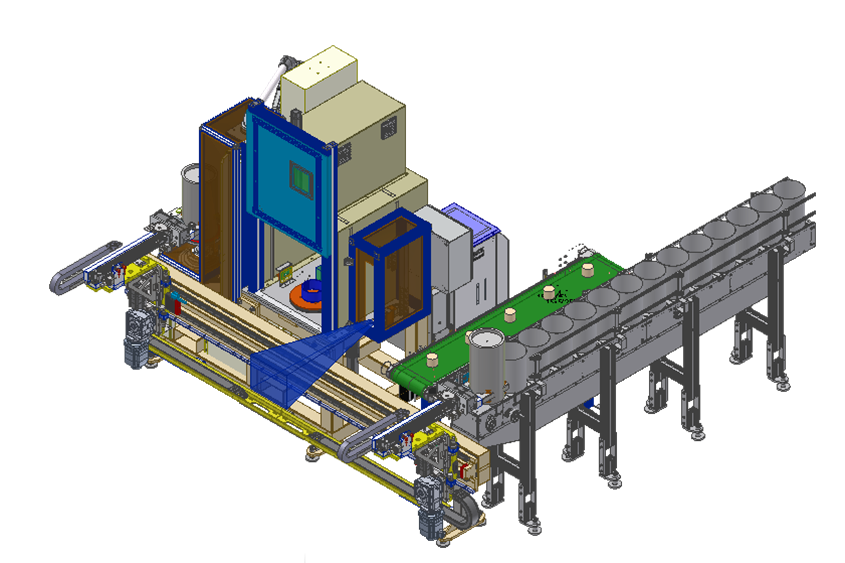

Jendamark’s range of standard canning modules can be configured in various ways on a production line to create a customised canning solution that meets the customer’s exact specifications.

Jendamark’s standardised canning machines can easily be arranged to form manual, semi-auto or fully automated canning lines. Whether the process is GBD or non-GBD controlled, post sizing (soft stuff) or pre-sizing (hard stuff), Jendamark has a solution. Our machines are proven in industry and cater for both passenger and commercial vehicle ranges.

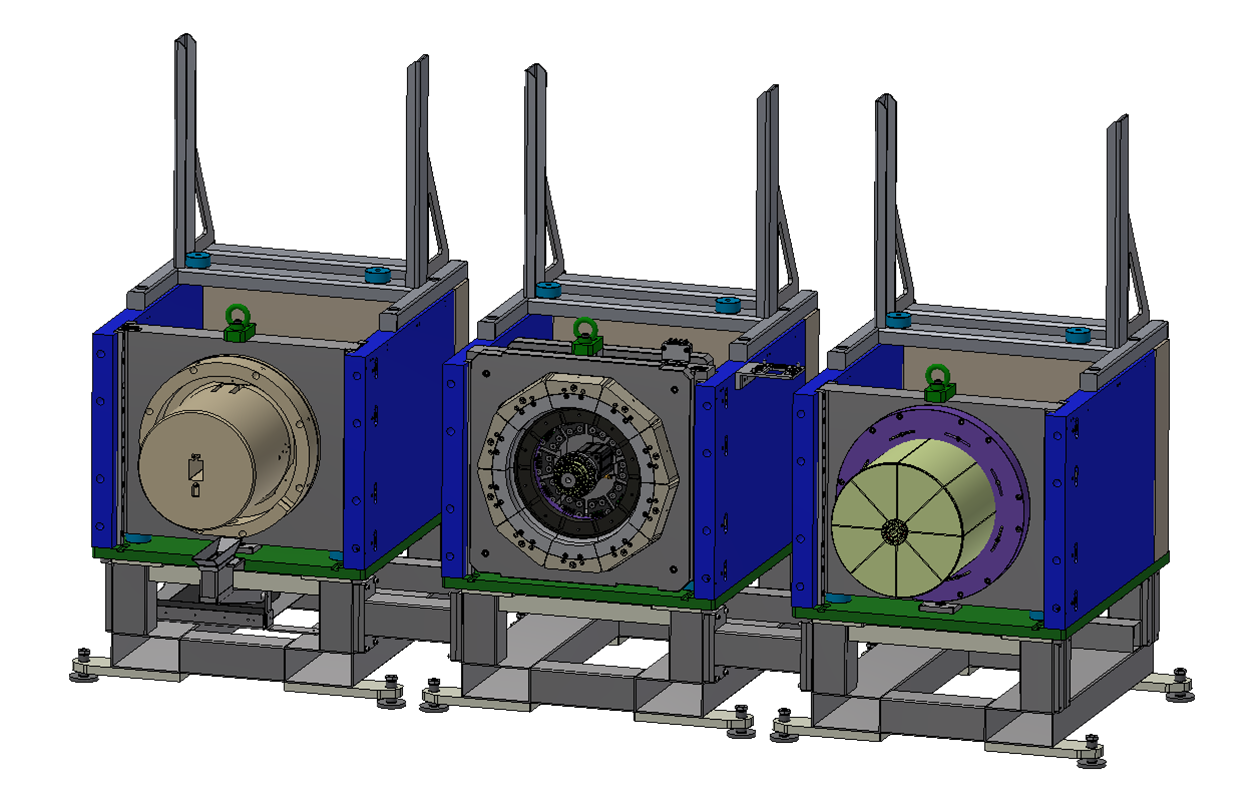

Economy Canning Modules

For customers seeking a simplified, cost-effective canning solution, Jendamark’s Econo line delivers a general option where less flexibility is required. Multiple modules are combined in a standard configuration and mounted on a single base plate.

Machine offerings in this range include the Econo Shrinker and the new Econo Measuring Machine.

Facilities

Mat Weighing

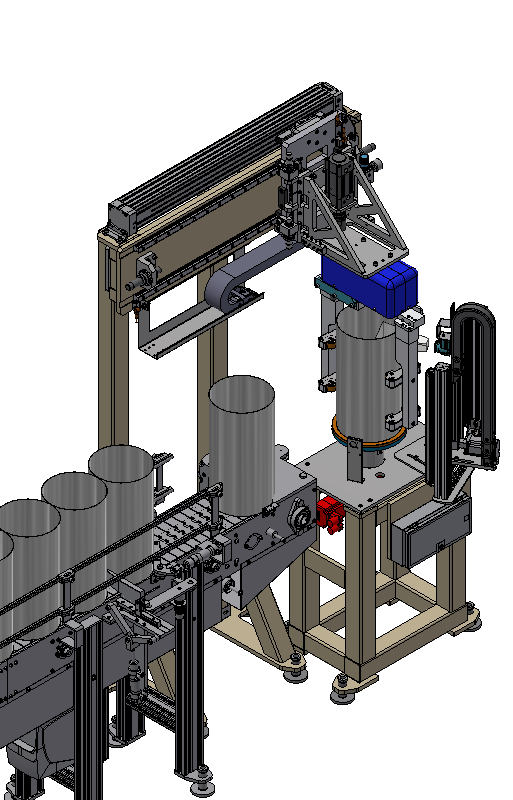

Auto Stuffing Press

|

|

|

Passenger Vehicle

|

Commercial Vehicle

|

Wrapping

Auto Stuffing Press

|

|

|

Passenger Vehicle

|

Commercial Vehicle

|

Mono Measuring

Measuring Machine

|

|

|

Measuring Machine (Manual)

|

Measuring Machine (Automatic)

|

Can Orientation

Can Orientation Machine

|

|

Can Orientation Machine (Automatic Cells)

|

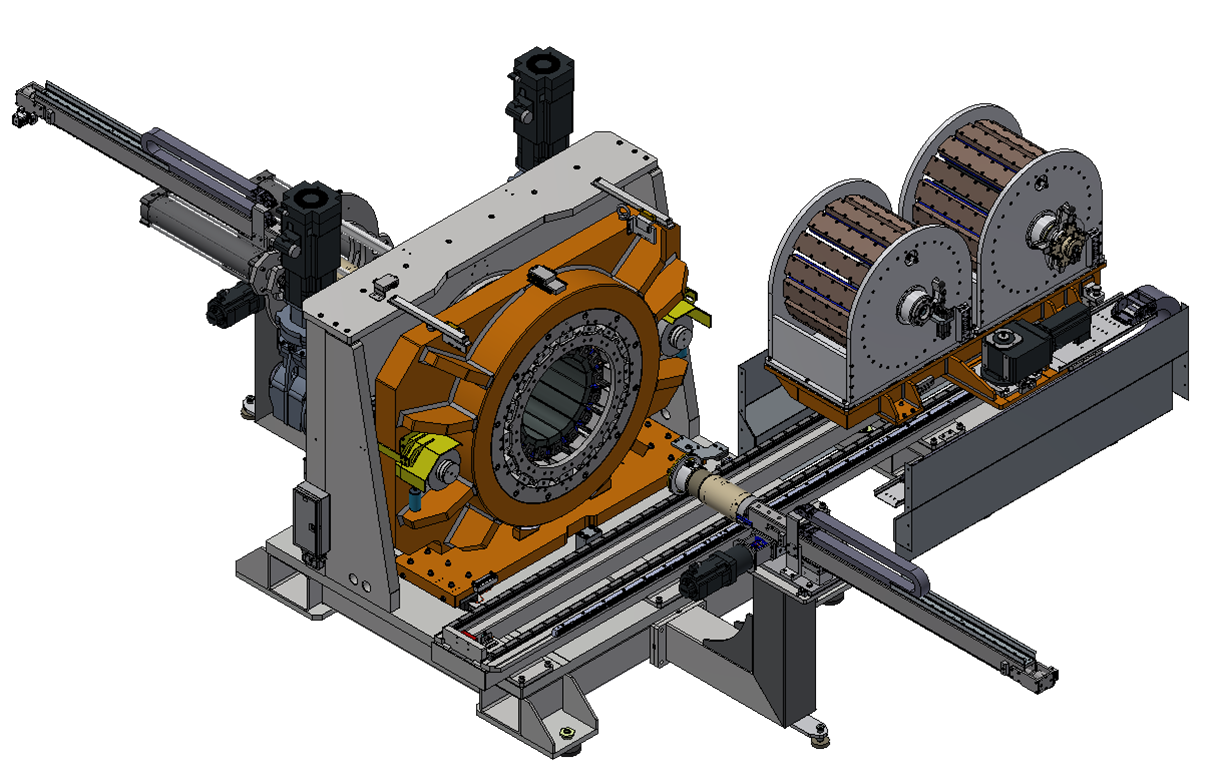

Stuffing

Auto Stuffing Press

|

|

|

Passenger Vehicle

|

Commercial Vehicle

|

End Can Forming

Forming Machines

|

|

|

Passenger Vehicle

Machine Types Include:

|

Commercial Vehicle

Machine Types Include:

|

|

|

Double Shrinking Machine

|

Can Expansion

Forming Machines

|

|

|

Passenger Vehicle

Machine Types Include:

|

Commercial Vehicle

Machine Types Include:

|

|

|

Double Shrinking Machine

|

Part Shrinking

Shrinking Machine

|

|

|

|

|

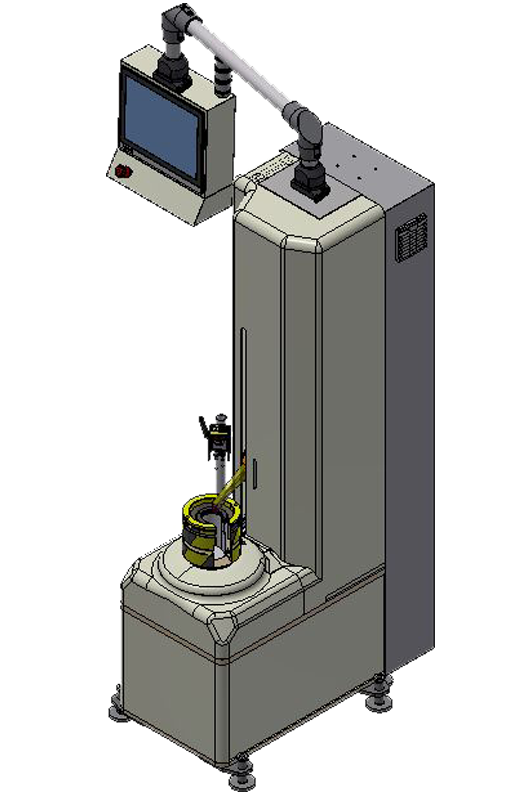

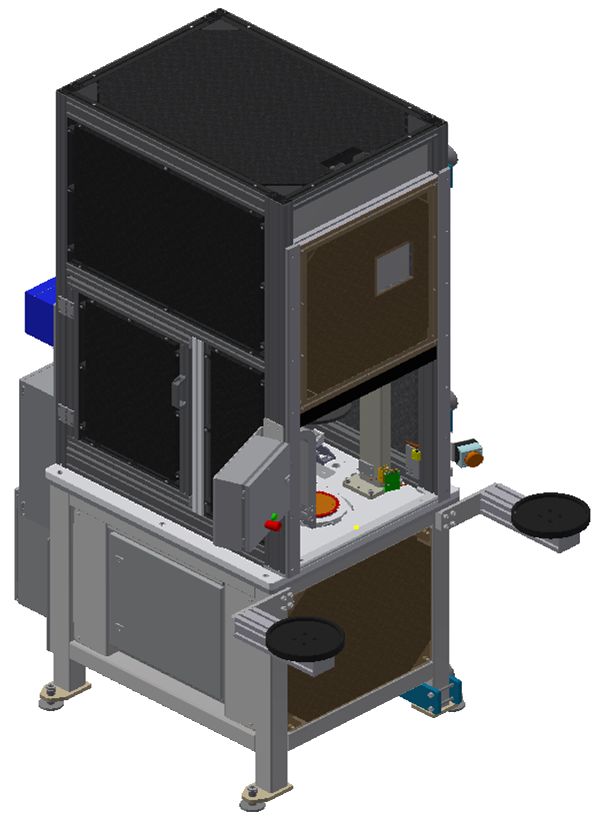

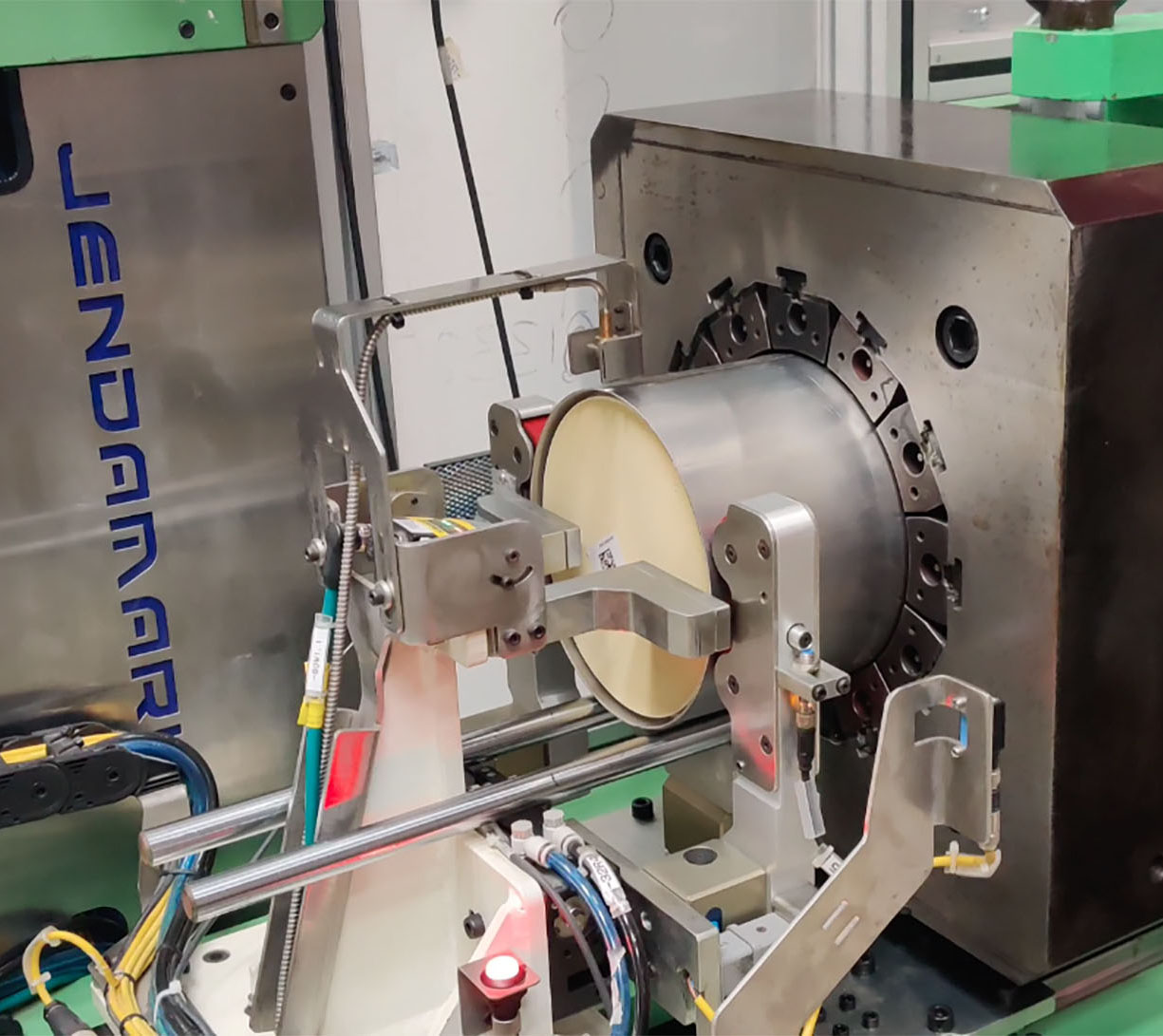

GBD Measuring

Measuring Machines

|

|

|

Measuring Machine (Manual)

|

Measuring Machine (Automatic)

|

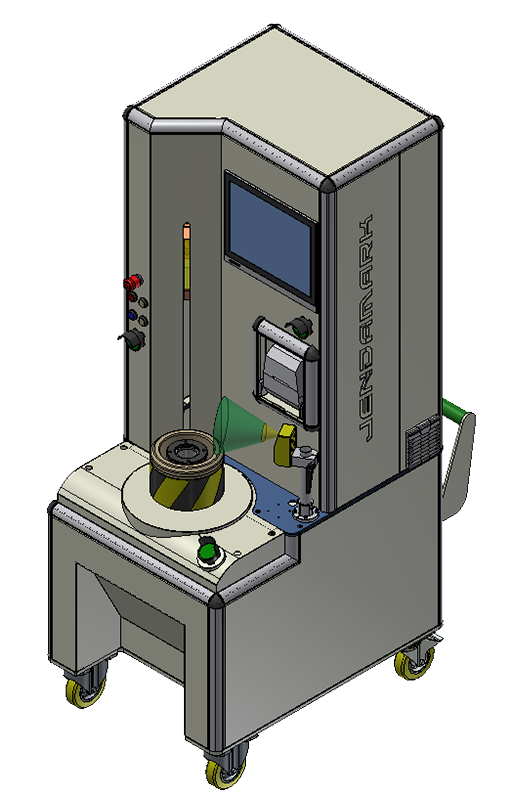

Marking

Marking Machines

|

|

|

Passenger Vehicle

|

Passenger Vehicle

|

Commercial Vehicle

|

|

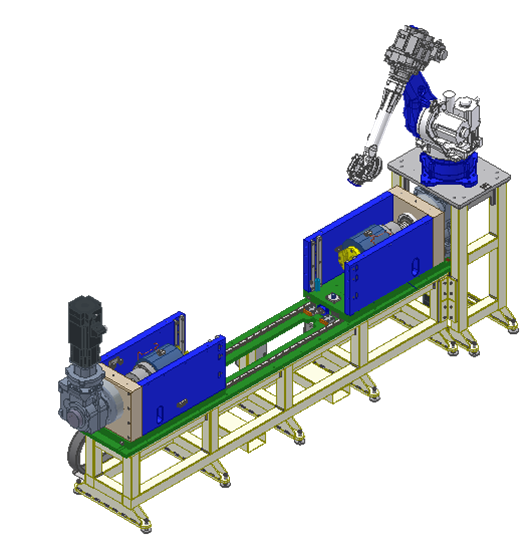

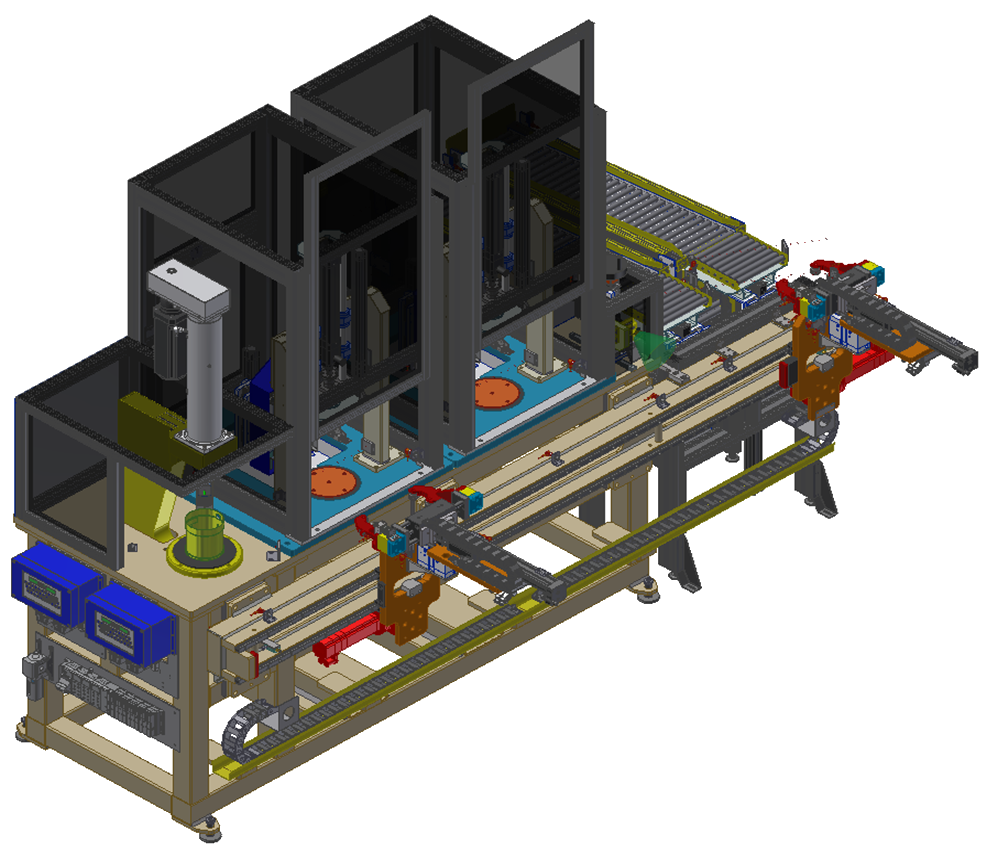

End-of-Line Assembly

Jendamark also offers end-of line assembly systems where the products that come off the canning lines are combined with other elements into a bigger assembly, ready for installation into the vehicle.

End-of-line assembly includes aspects such as testing, marking, gauging and checking to ensure that the finished product meets the highest quality standards.