by NewsAdmin | Feb 28, 2023 | Jendamark News

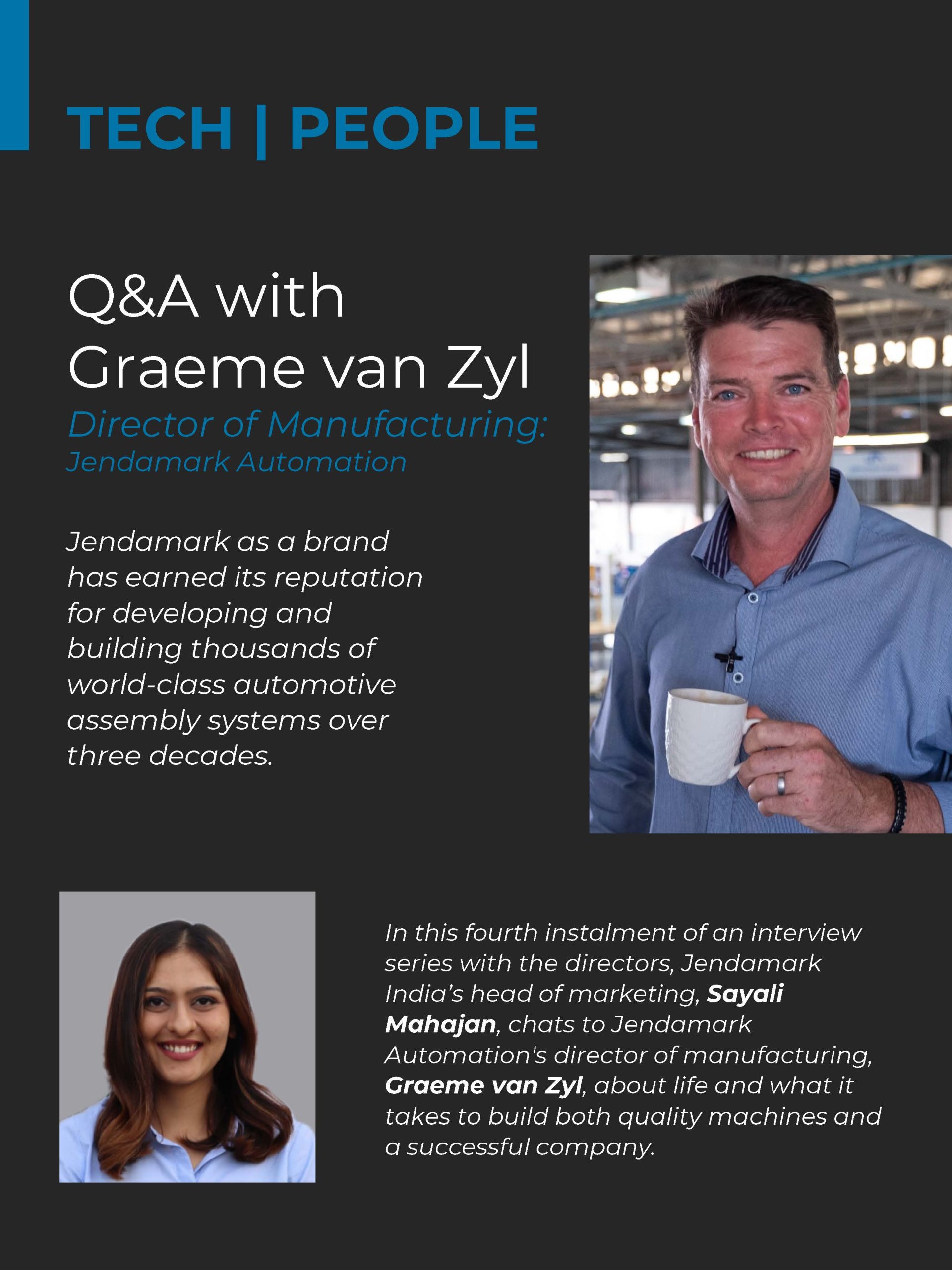

Jendamark as a brand has earned its reputation for developing and building thousands of world-class automotive assembly systems over three decades.

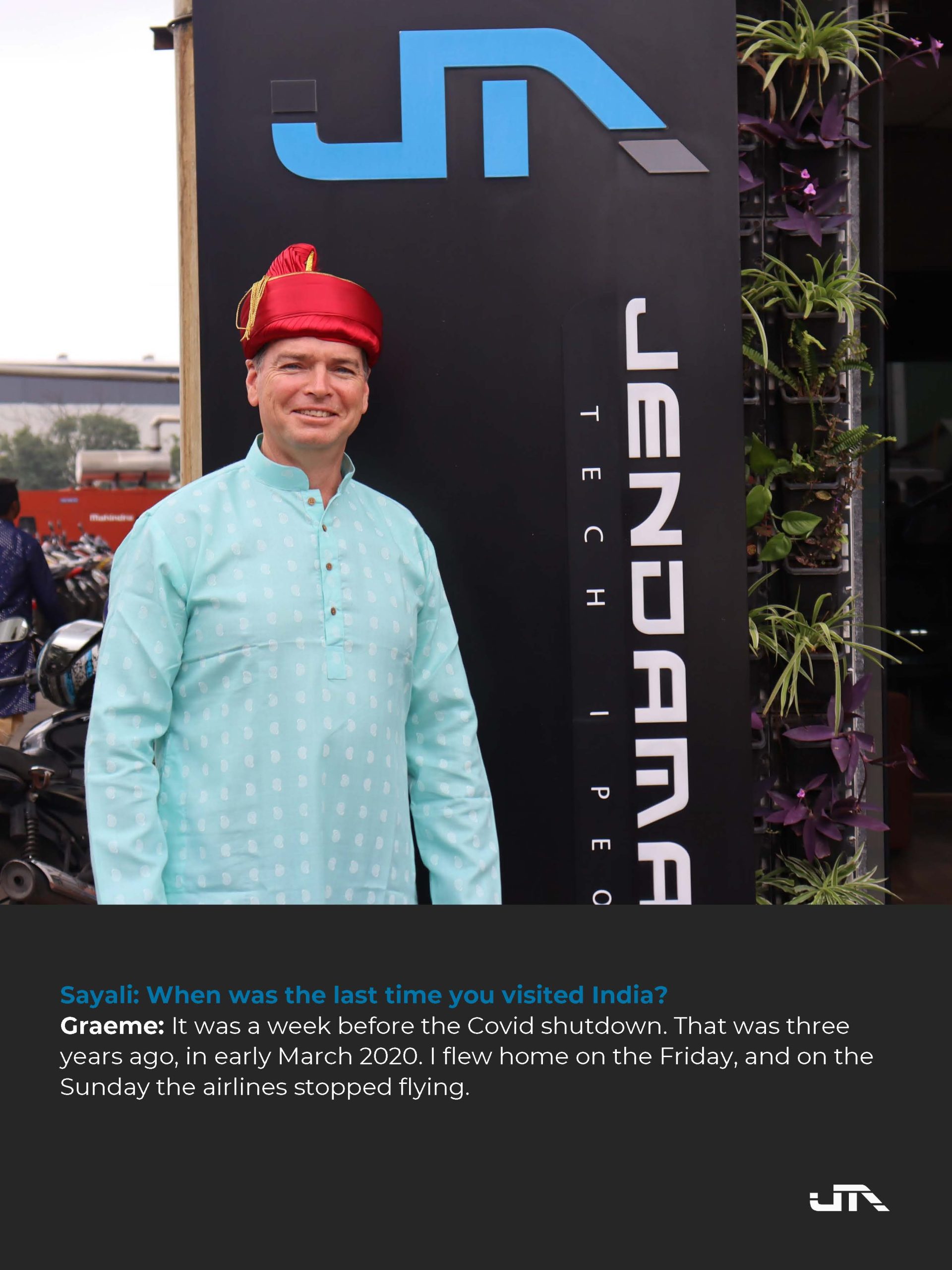

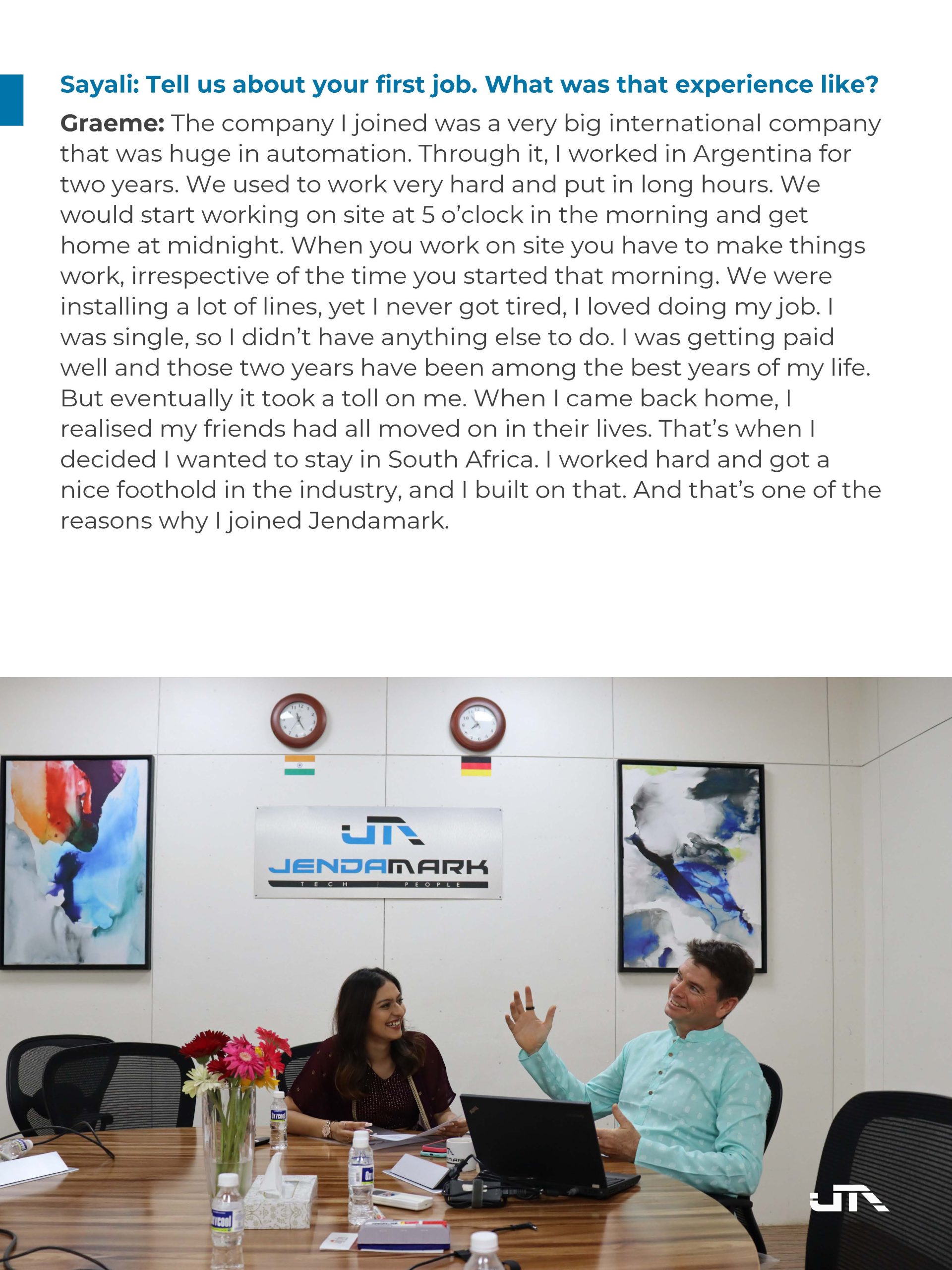

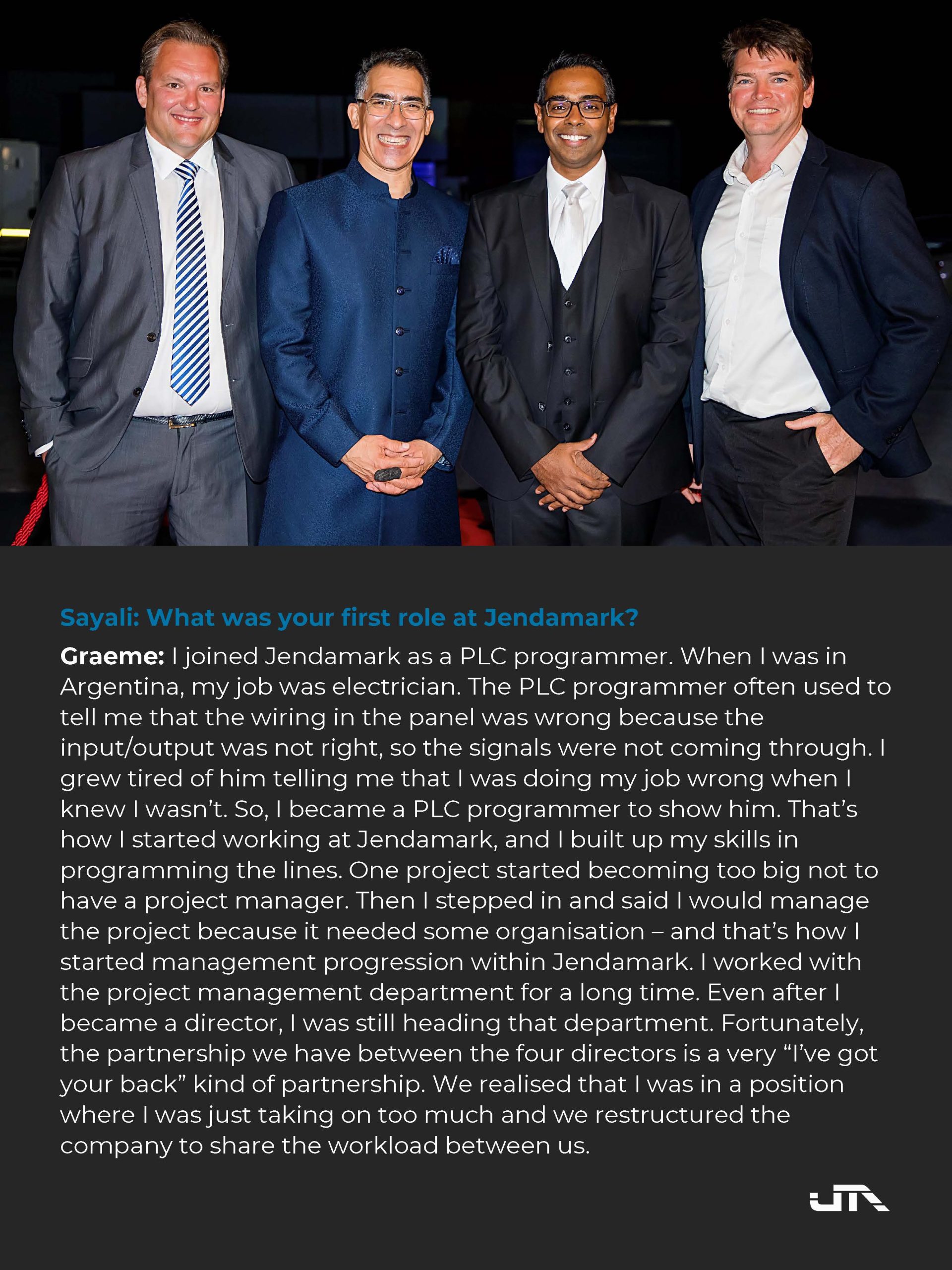

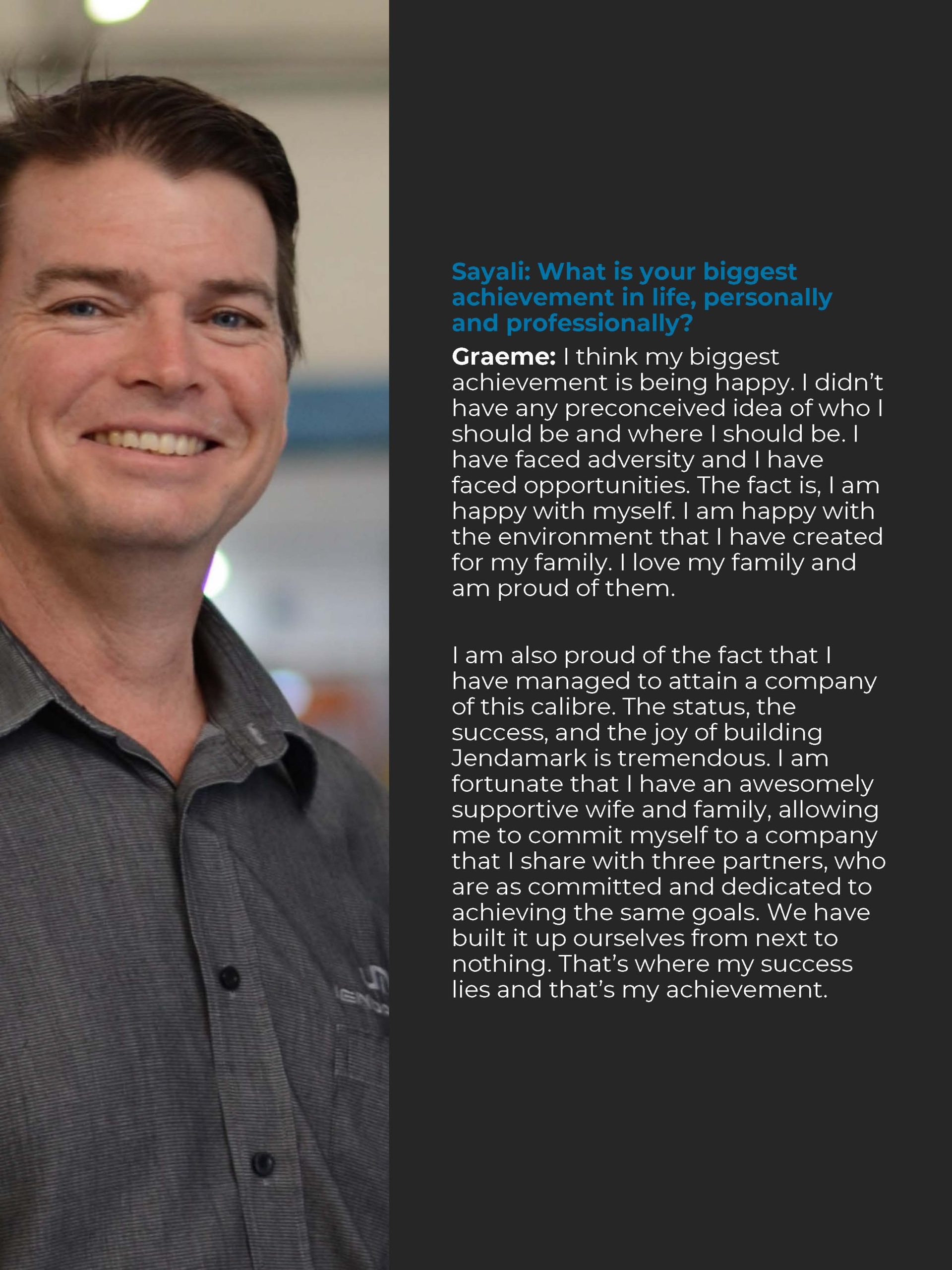

In this fourth instalment of an interview series with the directors, Jendamark India’s head of marketing, Sayali Mahajan, chats to Jendamark Automation’s director of manufacturing, Graeme van Zyl, about life and what it takes to build both quality machines and a successful company.

Click an image below to read the full interview:

by NewsAdmin | Feb 21, 2023 | Jendamark News

An unplanned, last-minute application saw mechanical engineering student Mrudula Joshi beat out a host of other applicants to claim one of two spots in the exciting new international exchange programme initiated by Jendamark India in partnership with MIT-World Peace University.

The 20-year-old Joshi is in her final year of her four-year B.Tech degree but it was her trailblazing involvement in an extracurricular technical club that secured her the two-week trip to South Africa. She is the first female driver for Team Piranha Racing – the university’s official Baja team and Overall Champions at BAJA SAE India in 2021.

The 20-year-old Joshi is in her final year of her four-year B.Tech degree but it was her trailblazing involvement in an extracurricular technical club that secured her the two-week trip to South Africa. She is the first female driver for Team Piranha Racing – the university’s official Baja team and Overall Champions at BAJA SAE India in 2021.

Baja teams design and build their own racing buggies from scratch, with members learning about all aspects of vehicle production from inventory to design, assembly, sales and management.

“My mom always said this is all boys’ stuff. There are no girl drivers. So, from my first year, I wanted to be a driver – that’s the thing I wanted to change,” says Joshi.

“I had no technical experience. During lockdown I learned the software; I always want to learn something new. I worked very hard to move up through the team.”

She says her all-male team has been very supportive and respectful. “They were so happy there was finally a girl. Girls bring emotional intelligence; we keep things neat and orderly. They’re happy about the changes in themselves – it’s a progressive environment.”

Her experience has made her even more determined to pursue a career in vehicle dynamics and testing, and the automotive software behind it.

“It’s true that girls often want to do the software side of things and not get their hands dirty. But if you go into industry, even on the automation side, you need to have basic mechanical skills and an understanding of how things work. An engineer knows how to solve problems.

“I’m doing my internship at an OEM, but I would like to gain experience in a company that is a Tier 1 supplier. That is where all the work happens, whereas the OEM is all about management. You need to have strong technical knowledge before going into management,” explains Joshi.

Through a range of programmes, events and seminars, Jendamark has been instrumental in exposing Joshi and her fellow students to the latest Industry 4.0 technologies, while helping MIT-WPU to develop a curriculum that ensures its students are workplace ready. Joshi’s older brother is one of the students who completed their final-year engineering internship with Jendamark India.

“Other companies are older, but they don’t want to change. Our generation has come with fresh minds. We always want to introduce something new and implement the new things with the existing ones,” smiles Joshi.

“Jendamark in India and South Africa has an amazing culture. The people are friendly, and you can explore opportunities in various departments.

“All aspects of engineering are involved in this automation company. Other companies go for the big things. Jendamark works on a small thing very hard. Right now, they are developing Odin – you could do anything with that software.”

She describes the trip to South Africa, which included visits to Nelson Mandela University’s School of Engineering and School of IT, the world-famous Addo Elephant Park, and, of course, Jendamark Automation’s headquarters, as an amazing experience.

“This is the first time that I’ve travelled without my family. My brother is so proud of me, and they always want to protect me, but now I know what I’m capable of.”

by NewsAdmin | Feb 7, 2023 | Jendamark News

Senior design engineer Reshma Jadhav recently travelled to South Africa where she spent two weeks learning the complexities of catalytic converters before taking up her new role as technical lead for Jendamark India’s canning division.

It has been a rapid rise for Jadhav, who joined Jendamark India just one year ago, after seven years with another automation company.

“At that company, the most complex project that I worked on was a cylinder head cam cover assembly line for a facility in China, which presented a number of challenges, including the cycle times on the line,” says Jadhav.

“Before I joined Jendamark India, I was never exposed to canning projects. So, my initial goal with this intensive training experience in South Africa was to learn all there is to know about the basics, including all tooling and facilities, so that I can impart this knowledge to my team in India.”

Jendamark’s South African team has been developing catalytic converter assembly facilities for almost three decades.

“When I started my training, I was given an induction by Alwyn Smit, who explained the entire design process flow, ensuring that I had a clear foundation. Then each member of the tooling team shared their personal process flow that they follow to ensure that a successful design is released every time,” explains Jadhav.

“I gained exposure to all the various checks that need to be done, the customer data that must be assessed, the tooling calculations that need to be done as well as the lessons learned from these calculations.

“I also learned about parametric modelling when designing multi-body assemblies, which is an incredibly helpful tool that can be used for designing canning tooling.”

Jadhav is excited to share all this newfound knowledge with her team, and see where improvements and increased efficiencies are possible.

She also takes back some fantastic travel memories such as taking time out to experience Gqeberha’s beautiful beaches, seaside flea markets, and game reserves with her colleagues.

“This opportunity is really exciting for me, and I accepted it with open arms. This is a fantastic opportunity for growth, and I will be eternally grateful for all the support and guidance. This new role is a way to develop my career in a well-established company and it’s a great position. I am excited to see what the future holds and looking forward to growing my team around me.”

Jadhav says, as a working mother, the flexibility that Jendamark offers with work-from-home initiatives makes it an adaptive environment that fits in with life’s daily challenges that can arise.

“The fact that Jendamark’s work globally is project-based means that every project we take on is challenging and different. No day is the same and I love coming up with innovative solutions to every one of the various challenges.”