by NewsAdmin | Oct 31, 2023 | Jendamark Junction

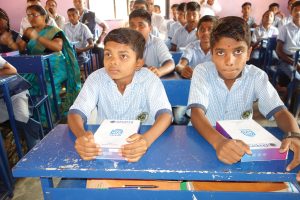

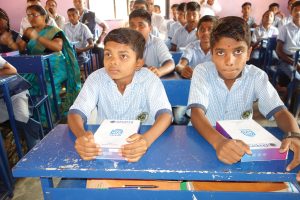

As part of a social investment partnership with Rotary International, Jendamark India and suppliers recently sponsored 38 Odin Education tablets to 8th grade students at the SAMPARC Gramin Vidya Vikas Kendra School in the village of Bhambarde in Mulshi Taluka.

SAMPARC, which stands for Social Action for Manpower Creation, is the brainchild of Shri Amitkumar Banerjee, who started this organisation of hope in 1990 for children of sex workers as well as orphans and destitute children. It works in Jendamark India’s home state of Maharashtra and in Rajasthan, West Bengal and Uttar Pradesh, offering services ranging from children’s homes to community education support programmes, industrial and vocational training centres, and schools.

SAMPARC, which stands for Social Action for Manpower Creation, is the brainchild of Shri Amitkumar Banerjee, who started this organisation of hope in 1990 for children of sex workers as well as orphans and destitute children. It works in Jendamark India’s home state of Maharashtra and in Rajasthan, West Bengal and Uttar Pradesh, offering services ranging from children’s homes to community education support programmes, industrial and vocational training centres, and schools.

SAMPARC started its second centre in Bhambarde to give poor children from nearby rural villages a chance to attend school. Recently named the best school in Mulshi Taluka, the award-winning Bhambarde Gramin Vidya Vikas Kendra now has a hostel and facilities for 281 students from the 5th to 12th grade and offers the finest computer class in the district.

Rotary Club of Pune Wisdom identified the school as the right fit for this ed-tech sponsorship. The 8th grade students were introduced to the Odin Education ecosystem and received their ed-tech tablets, which were pre-loaded with their syllabus content and related educational resources and learning platforms. As individual students engage with the device, they will also be served with content about specific subjects and activities they are interested in that don’t form part of their curriculum.

Rotary Club of Pune Wisdom identified the school as the right fit for this ed-tech sponsorship. The 8th grade students were introduced to the Odin Education ecosystem and received their ed-tech tablets, which were pre-loaded with their syllabus content and related educational resources and learning platforms. As individual students engage with the device, they will also be served with content about specific subjects and activities they are interested in that don’t form part of their curriculum.

Special thanks to Jendamark India’s partners in this project: Sandesh Cargo Movers, S.P. Engineering, Sai Industries, Shree Ganesh Packers, Santech Systems, Shruti Transport, Swiftin Corporation LLP, Access Industrial Sol, Sigma Tools & Machine Solutions, Swara Industries, and S.B. Rubber & Engineering Industry.

by NewsAdmin | Oct 27, 2023 | Jendamark Junction

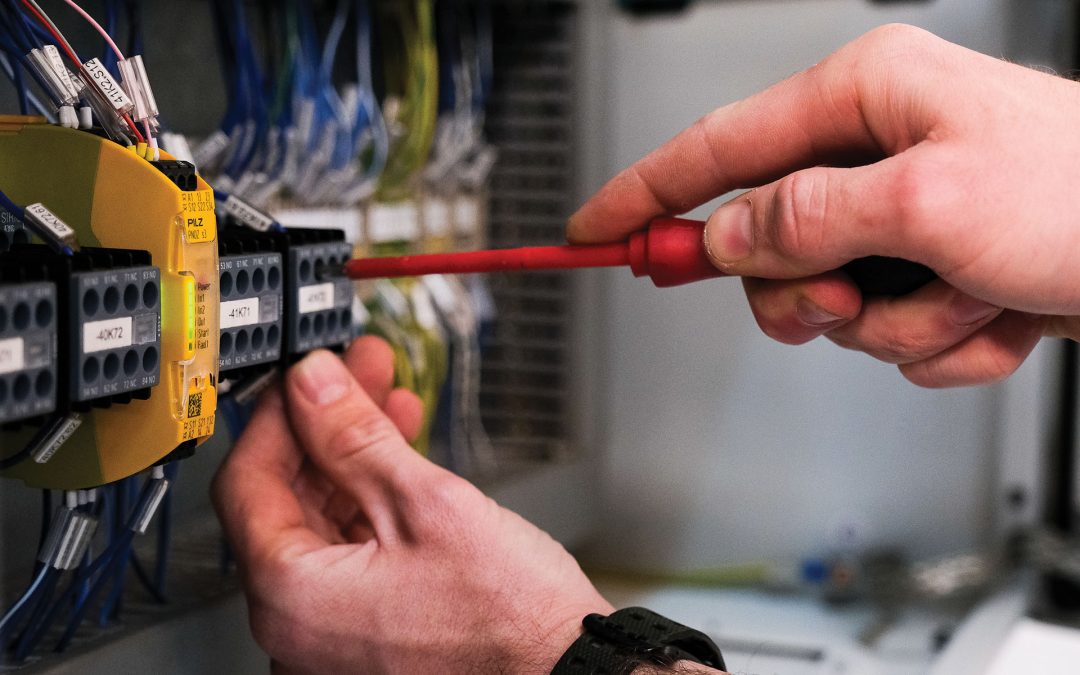

The Government of India has introduced a new set of rules under the AIS 156 banner, designed to regulate electric vehicle (EV) assembly, given the complexities and incomplete technical expertise of this burgeoning industry.

Electric vehicles have been holding their own since entering the global market, as they offer significantly lower running costs and less environmental pollution than internal combustion engine (ICE) vehicles. An EV consists of many electronic parts and a large cluster of wires connecting them to the battery and motor, which contributes more than 50% of the vehicle’s total weight and price.

Because battery packs tend to have more safety and operational issues than other components, the new AIS 156 regulations call for a data-driven assembly process and more control over the manufacturing of EVs.

Standard requirements

The AIS 156 standards require manufacturers to store cell grade and quality data, like Open Circuit Voltage (OCV) and Internal Resistance (IR), as well as the cell manufacturer data, against the serial number for each cell prior to assembly.

After assembly, the total battery pack OCV and IR must also be recorded, as it is mandatory to put the same grade of cells in a single battery pack. This is essential for maintaining the quality and safety of the EV.

According to Jendamark India director Himansha Jadhav, Jendamark has put automation solutions in place to help manufacturers measure these values and place cells as per their grading.

“ODIN Workstation records the data with which it controls the process to ensure that the graded assembly of battery packs is followed.”

“Another parameter is Ingress Protection (IP X7) standards for water and dust-resistant packaging of battery packs. Manufacturers will have to perform leak testing for which we provide automation, process security, and data capturing of leak and pressure values,” explains Jadhav.

In addition, AIS 156 also lists testing requirements for battery management systems, thermal management and charge-discharge of battery packs.

“For this, we have successfully integrated with the testing machines, and store data to decide whether the battery pack is built as per requirements. All this data can be seen against the serial number of each battery pack.”

Supporting complex assembly

Supporting complex assembly

“In India, up to 75% of workers are contract based, which results in an untrained and inexperienced workforce. Add to that the revolutionary and complicated nature of the EV product, and there is a clear need for extensive operator training and guidance,” explains Jadhav.

A process security system that will ensure product quality and protect the operator from harm is essential, he adds.

“In this era of Industry 4.0, manufacturers need data traceability, providing analytics for each process, and to be able to manage different variants on a production line.

“Jendamark’s homegrown software solution includes Odin Workstation, which handles all these complexities and ensures right-time assembly every time.”

Step-by-step operator guidance on an interactive touch screen allows workers to easily follow the set process for assembling each type of battery or variant, while enabling companies to spend less time on training.

“We’ve seen companies putting a lot of time, money and sweat into developing products and building prototypes necessary for the certification to launch the product, but that doesn’t always translate into the production being done with the same amount of care, comfort and expertise,” cautions Jadhav.

“We know there is a need to meet production volumes to fulfil market demand, but an incorrectly assembled product can be disastrous for any company, leading to product recall campaigns.”

Because ODIN Workstation is integrated with on-field devices like cameras, tightening tools, sensors and leak test machines, it will not allow the operator to skips steps. This ensures that products are correctly manufactured every time.

Looking ahead

Looking ahead

Jadhav expects data-driven process control to become a required norm in the near future.

“Manufacturers are already upgrading the manufacturing process to include a mix of automation and process security for their assembly line. This ensures optimum use of investments and 100% right production output.

“Jendamark, having developed and deployed such solutions, is already ahead and ready to deploy more such solutions. We have also dedicated substantial resources and already offer our customers new technology solutions such as AI-based vision systems, collaborative robots, and IOT sensors in proof-of-concept stage.”

Interested in our process security solutions? For more details, contact shashikant@jendamark.in

Complex EV assembly Solutions

Jendamark provides customised solutions, with built-in process security, for these EV assembly challenges:

- Potting and dispensing of phase-changing material in battery packs

- Cell sorting, grading and cell formation

- Laser welding of busbars to cell terminals

- Motor magnet dispensing and motor winding

- Handling electronic components with minimum manual intervention

- Thermal pad compression and strapping of battery packs

- E-transmission with gauging and shim selections or integrated drivetrains

- Torquing, traceability, testing and integration of all systems in one

by NewsAdmin | Aug 10, 2023 | Jendamark Junction

INDIA

INDIA

Jendamark India now boasts not one, not two, but three assembly halls to handle growing projects for customers. Our newest addition at the Pune head office includes a tech centre and display area featuring the Dobot collaborative robots.

SOUTH AFRICA

SOUTH AFRICA

This year, the manufacturing, assembly and design team celebrated the unveiling of their new mural. The giant artwork at the department entrance was created to spotlight the importance of the technical trades in growing Africa’s industrial sector and depicts Jendamark’s pride in our artisans.

GERMANY

GERMANY

Jendamark’s sales and service office in Penzing has been expanded and upgraded to provide a warm and welcoming base from which to serve our European customers.

COMING SOON

COMING SOON

Plans for the opening of our USA office are at an advanced stage, and we look forward to welcoming and serving our North American customers in the near future.

by NewsAdmin | Aug 2, 2023 | Jendamark Junction

Jendamark and Rubicon have been working together to serve our customers since the dawn of this millennium. The Covid-19 pandemic saw the partnership tested as we found new ways to overcome the ensuing supply chain problems. We asked the director of new business for the Rubicon Group, Dylan Schnetler, about how the partners rose to the challenge.

Q: When it comes to this partnership, what does each business bring to the table?

A: Rubicon supplies Jendamark with different technologies that add value to the solutions Jendamark builds for their customers. Our role is to keep Jendamark abreast of the latest technologies in the automation space. Once the tech is adopted by the Jendamark engineers, then Rubicon’s role is to ensure competitive pricing and secure supply both during and after the project. Our roles are complementary. By adding value, we enhance the offering and assist in growing Jendamark’s business, which in turn grows our business.

Q: During the pandemic, there were massive global supply chain issues. Tell us about the nature of these challenges and how you overcame them.

A: We had significant supply chain challenges due to component shortages globally and also stress on the logistics chain. This had both cost and timing implications in ensuring that Jendamark could meet their project timelines. Rubicon has a comprehensive automation offer, so we could always look within the group at alternative product sets to overcome these issues. With Jendamark’s support, we could motivate with supplier management teams to prioritise our shipments and their importance. Siemens products were a prime example, where we could leverage both historic and forward-looking demand to pre-empt stock at Rubicon specifically held for Jendamark.

Q: What is the most important thing when it comes to supporting Jendamark customers?

A: The most important aspect of this longstanding relationship is trust and transparency. Both Rubicon and Jendamark have always taken the approach of working together as a team to win for the mutual benefit of both companies. It is this foundation that leads to excellent communication between our companies on all levels and it starts from the top down. In addition, both companies are very proud of the fact that we originated in Gqeberha (formerly Port Elizabeth) and are truly local companies. We have embraced and not been intimidated to take our vision and ambitions to the global market.

Q: Do any stand-out projects come to mind?

A: The ELSD assembly line project for a customer in the USA. Jendamark had challenges with implementing vision systems that struggle with changing light conditions even when a fixed light source is introduced. A lack of support from suppliers in assisting with these issues was also a major concern. Rubicon proposed the Cognex vision system, which has now become an in-house standard at Jendamark, as it is more stable and easy to set up. Rubicon provides training and support to ensure the successful application of these solutions.

Tech Twist

In an interesting twist, Rubicon is now implementing Jendamark’s ODIN Manufacturing solutions at its new inverter production facility in Cape Town. Rubicon chief product officer Nick Roche says:

“We’re looking at how we can improve the previous production methodology with the goal of better efficiencies, better production quality and higher throughput. We believe that the ODIN technology fulfils these requirements and are looking at installing a proof of concept trial. Should that be successful, we will consider a larger investment in a full roll-out of the technology across the production facility.”

by NewsAdmin | Aug 1, 2023 | Jendamark Junction

After purchasing the controversial Seaview Lion Park in October last year, Jendamark has quietly set about transforming the revitalised Seaview Private Sanctuary into a haven of environmental conservation and upliftment that extends into the communities who live near the park boundaries.

Currently, the Sanctuary is in the process of being redeveloped as an outdoor eco-retreat for the company’s employees and customers. To this end, all the big cats have been rehomed, a dam has been constructed and various free-ranging wildlife species have been introduced.

Jendamark operations director Siegfried Lokotsch says that, while the park will not be open to the public, it is important that the wider Seaview community – including the informal settlements of New Rest and Zweledinga – benefit from it.

“Wherever Jendamark operates, we always try to involve the community and make a difference.”

“It’s important for us to give back not only to the animals but also to the people nearby.”

Creating awareness about taking care of the environment and keeping the surrounding area free of waste is an important first step,” says Lokotsch.

Five people from the local community have been contracted to carry out bush clearance and maintenance activities in the Sanctuary, while two more have been employed to do daily roadside litter clean-ups and assist people making use of the two municipal waste transfer sites in the area.

Waste management

Waste management

Seaview ward councillor Jason Grobbelaar says the relationship between Jendamark and the municipality began in January this year when he received a call from Lokotsch about the state of the Zweledinga waste transfer site.

“There was lots of dumping around the overflowing waste skip. I mentioned the issues to him that led to the surrounding litter and that it had been reported and would be attended to. I did not expect his next message: ‘Anything I can help with?’, which is where this journey started,” says Grobbelaar.

After securing permission from Nelson Mandela Bay municipal officials, Jendamark sponsored an additional skip for each of the Zweledinga and New Rest sites, as well as informational signage indicating what may or may not be dumped there.

“The assistance provided by Jendamark is filling the gap, as the municipality does not develop informal settlements where they will be moved to a new location in the near future, which is the case for Zweledinga,” explains Grobbelaar.

“It also closes the gap where the municipality at times battles to service the area over weekends and public holidays, or when truck breakdowns occur.”

A sporting chance

A sporting chance

Residents of the two informal settlements, who number around 800 in each, are also benefitting in other ways.

After Sanctuary custodian Jo-Ann Meiring noticed a young girl pouring paint in the dirt to outline a rustic netball court, the Jendamark team returned to lay and paint a permanent court, complete with hoops and inspirational signage. Two mobile action soccer nets were also sponsored, turning the court into a flexible sporting arena that is used daily by both young boys and girls in the area.

After Sanctuary custodian Jo-Ann Meiring noticed a young girl pouring paint in the dirt to outline a rustic netball court, the Jendamark team returned to lay and paint a permanent court, complete with hoops and inspirational signage. Two mobile action soccer nets were also sponsored, turning the court into a flexible sporting arena that is used daily by both young boys and girls in the area.

Zweledinga netball manager Jane Manisa says, “We are truly grateful for the wonderful and magnificent work that Jendamark has done for us.”

Care centres

Care centres

In preparation for the cold winter months, Jendamark also responded to a request for mattresses, blankets and an oil heater for the Sibabalwe Daycare Centre, along with a restored jungle gym from the park. Meiring says plans are underway for a similar care centre project at New Rest.

New Rest community leader Zoliswa Mkrayi says the people are very appreciative of the interventions and the positive impact so far.

“They built the sport field for our community, which is very beautiful, and employment opportunities decrease the number of unemployed in the area [which averages around 35%]. We are still looking forward to working hand in hand with Jendamark in the future.”

Lokotsch says giving people a hand up, not a hand-out, is central to Jendamark’s sustainable support strategy.

“If we can create a community where we uplift each other, and where each person thinks about the next person, we can build a much better place for everyone.”

by NewsAdmin | Jul 28, 2023 | Jendamark Junction

Educational technology, or ed-tech, is not a new concept, but the radical infrastructural approach that ODIN Education has developed is successfully bridging the digital divide in classrooms across India and South Africa.

Right now, there is a huge opportunity to transform education in developing countries, the head of ODIN Education, Ajit Gopalakrishnan, believes.

“The need for change in education isn’t new. Ed-tech itself isn’t new – some companies have been doing it for close to 20 years,” says Gopalakrishnan.

“But there are significant infrastructural challenges in developing countries that widen the digital divide. At ODIN Education, we believe we can fill in the gaps in accessibility to education and technology. Our aim is to be a complete infrastructure solution, and to develop a way for ed-tech to be implemented at scale.”

Full stack solution

Gopalakrishnan describes ODIN Education as a “full stack” solution.

“We put the entire infrastructure in place – everything from hardware to software, and we also provide support for what we call warmware – the students and teachers themselves.”

ODIN Education deploys ed-tech devices, personalised for every learner and pre-loaded with educational resources, which are all connected to the cloud server.

“It’s a safe, managed solution. Our system is closed, and the children can access only what we open to them,” he says, adding that analytics currently show substantial engagement – an average of 51 minutes per learner per day.

Where there are larger constraints such as poor connectivity in far-flung rural areas, the system provides a mix of online and offline resources.

Holistic education

“We don’t believe that fully online learning and teaching is the solution, but at the same time, traditional ways of teaching are outdated. So, our approach is a hybrid one, deploying tech into schools to sustainably augment the learning process.”

Essentially, Gopalakrishnan says, there are two problems to solve: access to resources and the education system itself.

“We cannot treat every child the same. We need a dynamic, personalised curriculum that understands the child and the environment they are in.

“I don’t believe we have a shortage of talent or passion. What we are creating is the infrastructure to find the talent and nurture it.

“The integration of AI helps us figure out what a particular child is good at and interested in, and then to connect that child to the resources they need to develop their talent. We can be pioneers in a new way of educating.”

ODIN Education is currently being rolled out with the support of private companies who have the vision to invest responsibly and sustainably in the future.

SAMPARC, which stands for Social Action for Manpower Creation, is the brainchild of Shri Amitkumar Banerjee, who started this organisation of hope in 1990 for children of sex workers as well as orphans and destitute children. It works in Jendamark India’s home state of Maharashtra and in Rajasthan, West Bengal and Uttar Pradesh, offering services ranging from children’s homes to community education support programmes, industrial and vocational training centres, and schools.

SAMPARC, which stands for Social Action for Manpower Creation, is the brainchild of Shri Amitkumar Banerjee, who started this organisation of hope in 1990 for children of sex workers as well as orphans and destitute children. It works in Jendamark India’s home state of Maharashtra and in Rajasthan, West Bengal and Uttar Pradesh, offering services ranging from children’s homes to community education support programmes, industrial and vocational training centres, and schools. Rotary Club of Pune Wisdom identified the school as the right fit for this ed-tech sponsorship. The 8th grade students were introduced to the Odin Education ecosystem and received their ed-tech tablets, which were pre-loaded with their syllabus content and related educational resources and learning platforms. As individual students engage with the device, they will also be served with content about specific subjects and activities they are interested in that don’t form part of their curriculum.

Rotary Club of Pune Wisdom identified the school as the right fit for this ed-tech sponsorship. The 8th grade students were introduced to the Odin Education ecosystem and received their ed-tech tablets, which were pre-loaded with their syllabus content and related educational resources and learning platforms. As individual students engage with the device, they will also be served with content about specific subjects and activities they are interested in that don’t form part of their curriculum.

Supporting complex assembly

Supporting complex assembly Looking ahead

Looking ahead

INDIA

INDIA SOUTH AFRICA

SOUTH AFRICA GERMANY

GERMANY COMING SOON

COMING SOON

Waste management

Waste management A sporting chance

A sporting chance After Sanctuary custodian Jo-Ann Meiring noticed a young girl pouring paint in the dirt to outline a rustic netball court, the Jendamark team returned to lay and paint a permanent court, complete with hoops and inspirational signage. Two mobile action soccer nets were also sponsored, turning the court into a flexible sporting arena that is used daily by both young boys and girls in the area.

After Sanctuary custodian Jo-Ann Meiring noticed a young girl pouring paint in the dirt to outline a rustic netball court, the Jendamark team returned to lay and paint a permanent court, complete with hoops and inspirational signage. Two mobile action soccer nets were also sponsored, turning the court into a flexible sporting arena that is used daily by both young boys and girls in the area. Care centres

Care centres