Odin Linewatch is a Jendamark software solution that delivers real-time production data straight from your assembly line. Get the information you need to make the right decision at the right time and manage production problems before they happen.

This smart Andon system displays all the data you need as it happens on an easy-to-read dashboard. At the end of each shift, Linewatch sends an email summary of these key parameters:

- Production target

- Shift progress and time

- Productivity chart

- Machine performance

- Product quality

- System uptime

- Inventory

- Yield with respect to variant

Linewatch highlights

- Shows attention-grabbing information first

- Exposes abnormalities in your production processes

- Presents actual status in rapid and simple way

- Quick interaction with user

- Provides all necessary information to analyse and optimise production

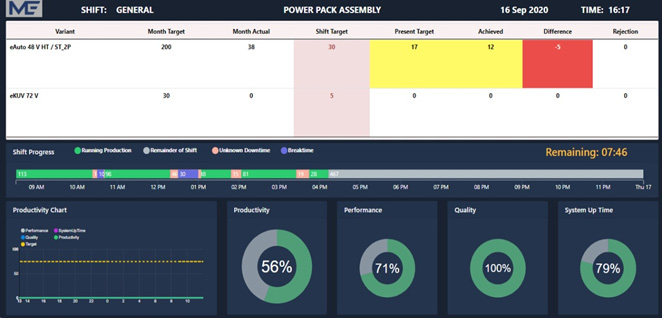

Screen 1: Example main screen

The main screen shows:

- The target set by Supervisor

- Monthly target

- Shift target

- Present target – automatically calculated by the cycle time set in the system

- Achieved – automatically calculated by system when part rolls off the line

- Rejection – if part is rejected on the line, it is automatically updated

- Shift progress bar

- Progress of the shift and system up time is shown in pie chart and bar graph

- Downtime, if any, initiated by the supervisor or not, is captured by the system

- Pre-defined breaks can also be shown in the progress bar

- Productivity graph and pie chart for productivity, quality and system up time

- Shows OEE graph with all the parameters

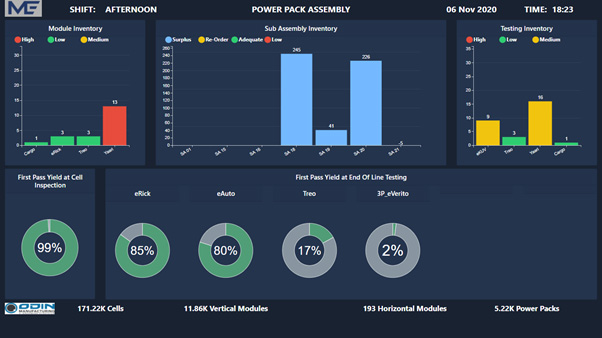

Screen 2: Example main screen

This screen shows:

- Line-specific inventory pile-up details

- With visual colour variation for triggering the supervisor for abnormal production rate i.e. low or high production

- Sub-assembly inventory pile-up details

- With visual colour variation for triggering the supervisor to re-access the production and add parts, or stop in case of excess production

- EOL testing details and inventory pile-up

- FPY for every variant

Please contact the Jendamark India team if you would like to know more.